Blog

Top 10 Benefits of Using Tableting Machines for Pharmaceutical Production?

In the pharmaceutical industry, efficiency and precision are paramount. Tableting Machines have revolutionized the production process, ensuring that tablets are produced with consistent quality. Dr. Emily Carter, a renowned expert in pharmaceutical technology, says, "Tableting Machines transform raw materials into reliable dosages." This highlights their critical role in manufacturing.

The benefits of using Tableting Machines extend beyond mere efficiency. They enhance production speed, reduce costs, and improve dosage accuracy. These machines allow for mass production while maintaining high standards. However, it's essential to reflect on the environmental impact of such machines.

While they boost production capabilities, manufacturers must consider sustainability and waste management. Balancing innovation with responsibility can be challenging. Nonetheless, the positive aspects of Tableting Machines cannot be ignored and promise a brighter future for pharmaceutical manufacturing.

Advantages of Enhanced Production Efficiency with Tableting Machines

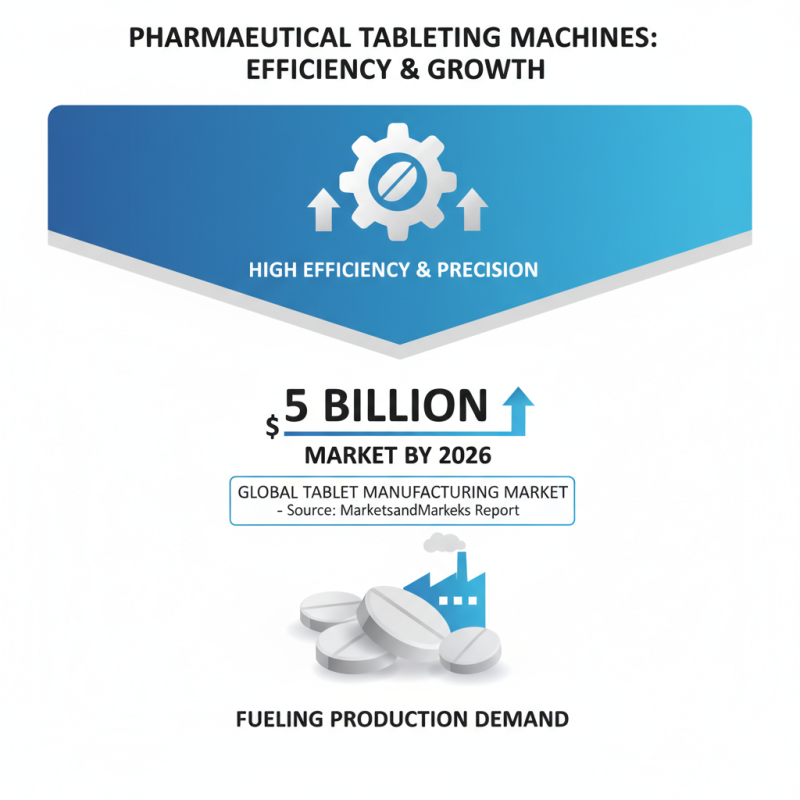

The pharmaceutical industry demands high efficiency and precision in production. Tableting machines meet this challenge effectively. According to a report by MarketsandMarkets, the tablet manufacturing market is expected to reach $5 billion by 2026. This growth underscores the demand for enhanced production efficiency.

Tableting machines allow for high-speed production. Some machines can produce thousands of tablets per minute. This capability significantly reduces operational time and costs. A study indicated that companies using these machines can boost output by over 30%. However, this efficiency sometimes comes with quality control concerns. Machines require regular calibration and maintenance to ensure uniform tablet strength and dosage.

Moreover, automation minimizes human error, yet it introduces its own set of challenges. Proper training for staff is essential to operate these machines. Mismanagement can lead to production delays and quality issues. Balancing speed and accuracy remains a point for continuous reflection in the industry.

Improved Consistency and Quality Control in Tablet Manufacturing

In tablet manufacturing, consistency is key. Tableting machines help achieve uniformity in dosage and texture. Each tablet produced is more likely to match in size and weight. This uniformity ensures that patients receive the correct amount of medication every time. Improved machinery also reduces human error, a significant factor in maintaining quality control.

However, reliance on automation does come with challenges. Operators may need extensive training to understand the equipment fully. Misalignment can occur, leading to unpredictable results. Each batch should be closely monitored to prevent any discrepancies. Regular maintenance is essential to maintain machine performance. The cost of repairs can also escalate if issues are not identified early.

Despite these drawbacks, the benefits often outweigh the challenges. Enhanced quality control mechanisms can lead to better patient outcomes. With precision engineering, the manufacturing process becomes streamlined. Continuous feedback loops can facilitate improvements in production. Ultimately, investing in tableting machines can elevate the standards of pharmaceutical production, but careful management is crucial.

Top 10 Benefits of Using Tableting Machines for Pharmaceutical Production

Cost Reduction Benefits of Automating Pharmaceutical Production

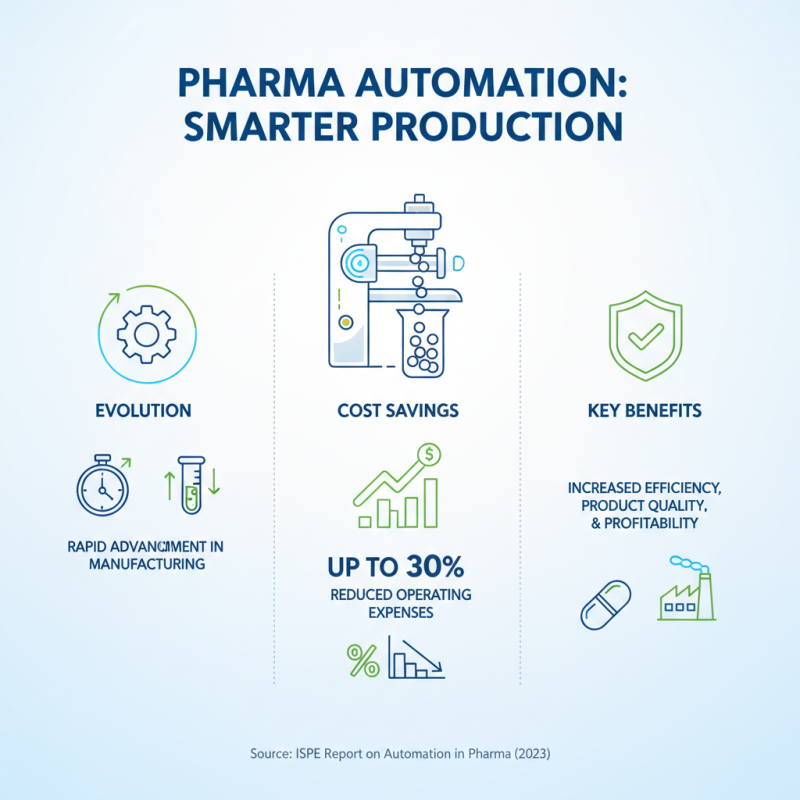

Pharmaceutical production is rapidly evolving. Automating processes with tableting machines offers significant savings. According to a report by the International Society for Pharmaceutical Engineering, manufacturers can reduce costs by up to 30% through automation. This is an attractive incentive for many companies.

Automation not only lowers labor expenses but also minimizes human error. Human interventions can lead to inconsistencies and rework, driving up costs. A study from the National Institute for Pharmaceutical Technology found that achieving consistency through automated systems saved companies an average of $2 million annually. However, switching to automation isn’t without challenges. Initial setup costs can be high, requiring thoughtful budgeting.

Tip: Assess your production scale before investing. Smaller operations might benefit from gradual automation. A phased approach allows for adjustments and minimizes risks. Efficiency gains are essential, but over-reliance on machines can pose risks. Keeping human oversight is crucial to maintaining quality control.

Implementing new technology requires training. Employees must understand how to operate and troubleshoot machines effectively. This investment in human resources is vital for maximizing the benefits of automation. Consider ongoing training programs as part of your strategy. Balancing tech and talent is key in modern pharmaceutical production.

Versatility of Tableting Machines in Drug Formulation

Tableting machines play a vital role in drug formulation. Their versatility allows for creating various tablet sizes and shapes. These machines can handle different materials, such as powders and granules. This adaptability is essential for formulating multiple drug types. From simple analgesics to complex combination therapies, tableting machines meet diverse needs.

The efficiency of these machines is notable. They can produce large batches quickly. However, the process requires careful monitoring. Variations in composition can lead to inconsistent tablet quality. This is where human oversight is crucial. Operators must frequently check the output quality. It’s a balancing act between automation and manual quality assurance.

In addition, tableting machines can accommodate different production scales. Whether it's a small lab batch or mass production, they can adjust accordingly. Yet, maintaining flexibility while ensuring quality control can be challenging. The industry must continue to refine techniques, ensuring optimal results. Even minor tweaks can affect outcomes, highlighting the importance of precise calibration.

Streamlining Compliance with Regulatory Standards in Pharma Industry

In the pharmaceutical industry, compliance with regulatory standards is critical.

Tableting machines play a significant role in ensuring this compliance. By automating the production process, these machines minimize human error, leading to consistently high-quality products. They also facilitate accurate dosage, which is essential for patient safety and efficacy of medications.

Tip: Implement regular maintenance checks on tableting machines to avoid unexpected downtime. Ensuring the machinery operates optimally is key to meeting production schedules.

Using advanced technology, tableting machines can adapt to various formulations. This versatility allows for quicker adjustments when regulations change. However, staying updated on the latest regulatory requirements presents a continuous challenge.

Manufacturers must invest time and resources into training staff on compliance matters.

Tip: Create a compliance checklist for each production run. This can help identify potential issues before they arise and enhance overall production efficiency.

Related Posts

-

Mastering Natoli Tablet Press Techniques for Optimal Performance

-

Top 10 Natoli Tablet Press Benefits and Features to Know?

-

How to Optimize Tablet Presser Efficiency with Data Driven Insights on Compression Techniques

-

What is a Tablet Presser and How Does it Work?

-

Why Choose Natoli Tablet Press for Your Pharmaceutical Manufacturing Needs

-

What is Natoli Tablet Press and How Does It Improve Tablet Production