Blog

What is the Best Capsules Filling Machine for Your Business?

Choosing the right Capsules Filling Machine can significantly impact your business. Expert John Miller stated, "Efficiency in filling capsules is key to maximizing production." This highlights the importance of selecting a machine that meets your specific needs.

Time is money in the pharmaceutical industry. A slow or inefficient Capsules Filling Machine can lead to delays and increased costs. It's essential to consider your production scale, the size of capsules, and the type of materials used. Many businesses overlook these details, which can result in poor performance.

Finding a balance between automation and manual operation can be challenging. Some machines promise high efficiency, but they may not suit smaller batches. It's helpful to reflect on what your business truly needs, rather than succumbing to flashy features. Investors often make mistakes by prioritizing speed over quality. By carefully evaluating your options, you can find the right Capsules Filling Machine that will grow with your business.

Understanding Different Types of Capsule Filling Machines Available

When considering the best capsule filling machine for your business, it is essential to understand the different types available. Manual machines are simple to operate. They require hands-on involvement but are affordable. These machines work well for small batches. However, they can be time-consuming for larger productions.

On the other hand, semi-automatic machines strike a balance between efficiency and control. They speed up the filling process without sacrificing quality. Users still need to monitor the operation, which may lead to inconsistencies if not managed properly. Fully automatic machines offer the greatest efficiency. They handle the entire process from filling to sealing. Yet, they come with higher costs and require more maintenance. Businesses must consider their production needs carefully.

Choosing the right machine isn’t straightforward. It involves weighing costs against efficiency. You might find yourself questioning the scalability of your choice. Do you have the right level of demand to justify a fully automatic machine? Reflect on your workflow and long-term goals before making a decision.

What is the Best Capsules Filling Machine for Your Business?

| Type of Machine | Filling Capacity (Capsules/Hour) | Power Consumption (Watts) | Dimensions (L x W x H, cm) | Weight (kg) |

|---|---|---|---|---|

| Manual Capsule Filling Machine | 1,000 | 300 | 30 x 25 x 20 | 2.5 |

| Semi-Automatic Capsule Filling Machine | 3,000 | 500 | 40 x 30 x 25 | 5.0 |

| Fully Automatic Capsule Filling Machine | 10,000 | 1000 | 100 x 50 x 40 | 150.0 |

| Desktop Capsule Filling Machine | 500 | 250 | 25 x 20 x 15 | 1.5 |

Key Features to Consider When Choosing a Capsule Filling Machine

When selecting a capsule filling machine for your business, several key features stand out. Production capacity is critical. A machine should meet your production needs without too much downtime. Think about your current and future demands. A smaller operation may need a manual option, while larger businesses often require automatic machines. Size and scale impact production efficiency.

Another important aspect is ease of use. Operators should be able to navigate the machine effortlessly. Complicated controls can frustrate staff and slow down production. Look for user-friendly interfaces with clear instructions. Maintenance is often overlooked but should be prioritized. A machine that is too complicated to clean can lead to hygiene issues and contamination risks.

Consider the type of capsules you will be using. Machines can handle different sizes and materials. Pay attention to the design and durability of the machine. It must withstand the rigors of daily use. Often, businesses overlook these factors in pursuit of lower costs. Making the right choice requires a balance of efficiency, user-friendliness, and cost-effectiveness. Each feature has its strengths and weaknesses that deserve your attention.

Analyzing the Cost-Effectiveness of Capsule Filling Machines

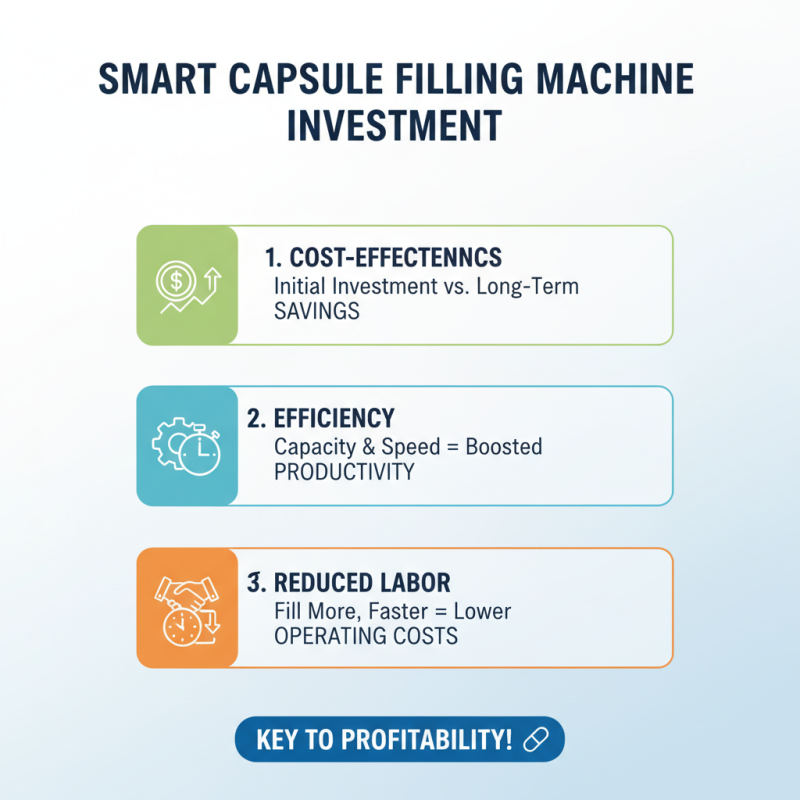

When choosing a capsule filling machine, cost-effectiveness is key. The initial investment might seem high, but a good machine can save money in the long run. Consider the machine's capacity and speed. A more efficient machine can fill more capsules in less time. This boosts productivity and can reduce labor costs.

Tip: Evaluate your production needs before purchasing. Understand your daily output requirements. It helps in selecting the right machine.

Look for machines that require minimal maintenance. Breakdowns can be costly. An unreliable machine not only disrupts production but may also lead to financial loss. Ensure you have access to parts and support if needed.

Tip: Research user reviews online. They can provide real insights into reliability and performance.

Ultimately, investing in a quality machine impacts your bottom line. A cheap machine might save money upfront. But it can lead to bigger issues later on. Think about longevity. Assessing the long-term benefits is crucial.

Evaluating the Production Capacity Needed for Your Business

When selecting a capsules filling machine, understanding your production capacity is vital. According to industry reports, many small to medium-sized businesses require machines with a capacity ranging from 1,000 to 10,000 capsules per hour. This figure reflects the growing demand for supplements and herbal products. If your projections suggest higher sales volumes, consider machines that can fill 15,000 capsules per hour or more, but keep in mind the initial investment will be significant.

Production capacity must be balanced with your current and projected business needs. For example, if your current sales are modest, investing in a high-capacity machine may not be prudent. Reports suggest that businesses often overestimate their needs, resulting in idle machines and wasted resources. Starting with a smaller, versatile machine may provide a more adaptable solution as your production needs grow.

It's essential to assess your workspace and the required automation level. Some machines take significant floor space and require advanced training. If flexibility is vital, you might want to invest in a semi-automatic option. Evaluating the level of user-friendliness and maintenance needs is equally important, as these factors can affect your overall productivity. Think carefully about balancing cost and efficiency.

Top Brands and Models of Capsule Filling Machines on the Market

When choosing a capsule filling machine, several brands stand out in the industry. Each model offers unique features tailored to specific business needs. Some machines are designed for larger batches, while others focus on precision and efficiency for smaller operations. Assessing your production volume is critical. Invest time to compare the speed, capacity, and ease of use of different models.

Design is another important aspect. Ergonomics and user interface play a role in how well the machine integrates into your workflow. You may find some machines complicated to operate. Others might seem perfect but lack the features you need. Don't overlook customer reviews. They can provide insight into long-term performance and reliability.

Consider maintenance requirements as well. Some machines may demand frequent downtime for upkeep. This can affect your productivity. What seems like a good deal initially may become a burden. Ensure you choose a model that balances cost and functionality. Exploring various options will help you make a more informed decision.

Top 5 Capsule Filling Machines by Production Capacity

This chart displays the production capacity of the top 5 capsule filling machine models available in the market. The data indicates their potential output per hour, which is an important factor when selecting a machine for your business needs.

Related Posts

-

How to Choose the Right Capsules Filling Machine for Your Production Needs

-

Revolutionizing Your Production Line: The Ultimate Guide to Capsules Filling Machines

-

What is a Capsules Filling Machine? Benefits, Types, and How It Works

-

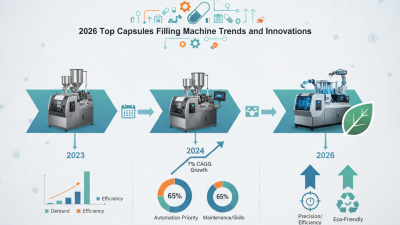

2026 Top Capsules Filling Machine Trends and Innovations?

-

Common Issues Faced by Businesses When Choosing Capsule Packaging Machines

-

What is Capsule Filling Equipment and Its Impact on Pharmaceutical Production Efficiency?