Blog

Best Tablet Pressers for Efficient Production in 2026?

In the evolving landscape of pharmaceutical manufacturing, the role of the Tablet Pressers is pivotal. According to a recent report by Grand View Research, the global tablet press market is expected to reach $2.5 billion by 2026, reflecting a robust demand for efficient production. Companies are looking for innovations to enhance output and reduce costs.

Dr. Emily Carter, an expert in pharmaceutical equipment, states, "The right tablet presser can significantly improve both quality and efficiency." This highlights the need for manufacturers to invest in high-quality equipment. Selecting the best tablet presser will not only streamline production but also mitigate common issues like inconsistent tablet hardness or weight variability.

However, challenges remain. Many producers still face difficulties in optimizing processes. Companies must reflect on their current practices and consider technological upgrades. The future of tablet production hinges on careful selection of equipment and a commitment to constant improvement in manufacturing techniques. As the market continues to grow, so does the necessity for reliable and efficient tablet pressers.

Key Features to Consider in Tablet Pressers for 2026

The tablet pressing industry is set for significant advancements in 2026. The key features to consider in tablet pressers will focus on efficiency, precision, and adaptability. Reports suggest that manufacturers will prioritize machines that can consistently produce high-quality tablets at faster rates. A recent study indicated that the demand for high-speed production could rise by 40% in the next few years. This means having the right tablet presser can greatly impact production workflows.

Another essential aspect is the integration of smart technology. Automated controls and data analytics will be vital in optimizing production. Industry experts predict that nearly 70% of production facilities will adopt some level of automation by 2026. Flexible equipment will enable quick adjustments between different tablet formulations. This adaptability is crucial as the market demands more personalized medicine solutions. However, it poses challenges in terms of training staff to handle advanced machinery, which can be overlooked.

Moreover, manufacturers must not ignore sanitation features. With increasing regulatory scrutiny, ensuring machines are easy to clean is essential. A report highlighted that around 30% of production downtime is due to equipment cleaning. Thus, tablet pressers designed with easier disassembly will be in high demand. Companies need to reflect on these aspects to stay competitive.

Top Innovations in Tablet Press Technology for Efficient Production

The tablet press technology is evolving rapidly. In 2026, innovations are transforming production efficiency. Recent industry reports highlight that the market for tablet press machines is expected to grow by over 7% annually. This growth stems from advancements in machinery and the rising demand for pharmaceuticals.

Modern tablet pressers now feature enhanced automation. These machines reduce manual intervention, minimizing human error. A report by PharmaTech noted that automated systems can boost production by up to 50%. However, integration of these systems can pose a challenge. Staff training is essential for maximizing the benefits of automation.

Here’s a tip: Regular maintenance of tablet pressers is critical. Neglecting this can lead to downtime and reduced output quality. Operating at peak performance also requires an understanding of material properties. Not all formulations are suitable for every press, and this requires careful analysis.

Innovations in Tablet Press Technology for Efficient Production

This chart represents the efficiency improvements of various tablet press technologies anticipated in 2026.

Comparative Analysis of Leading Tablet Press Brands in 2026

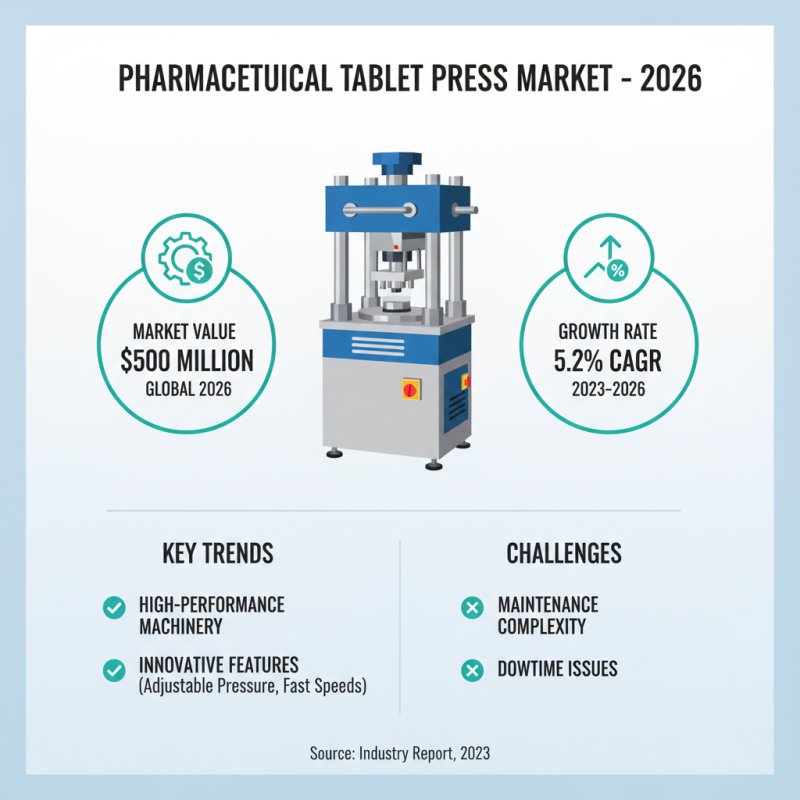

In 2026, tablet pressers are crucial for efficient production in pharmaceuticals. A recent industry report shows that the global tablet press market is expected to reach $500 million by 2026, growing at a compound annual growth rate (CAGR) of 5.2%. This growth highlights the increasing demand for high-performance machinery. Leading brands have introduced innovative features like adjustable pressure settings and fast production speeds. However, many companies still face challenges with maintenance and downtime.

Comparative analyses indicate that not all tablet pressers are created equal. Efficiency can vary significantly even within the same production line. The data suggests that usage errors contribute to nearly 25% of production delays. Training operators effectively is essential. For example, investing in operator education could potentially reduce error rates and enhance overall efficiency. The best-performing machines often come with advanced technology, yet they may require more comprehensive training for staff.

Moreover, sustainability has become a pressing concern. Some brands are moving towards greener production methods. However, not all manufacturers have adapted. The gap in adopting sustainable practices can lead to a competitive disadvantage. Certain models are still reliant on outdated technologies, which may compromise quality and efficiency. Companies need to critically assess their equipment choices and align them with current market trends for optimal results.

Best Practices for Optimal Tablet Production with Modern Pressers

Tablet production relies heavily on efficient tablet pressers. These machines must be able to handle various formulations and produce consistent results. According to a recent industry report, the global tablet manufacturing market is projected to grow at a CAGR of 7.5% from 2021 to 2026. This rapid growth emphasizes the need for best practices in using modern tablet pressers to meet demand.

Operators must understand the importance of adjusting compression settings. A slight miscalculation can lead to tablet defects. A study highlighted that up to 10% of tablets may fail quality checks if the settings are not precise. Optimizing feed frame speed also plays a crucial role. Ensuring a steady flow of powder can significantly reduce production downtime. Many manufacturers still overlook this detail, leading to unnecessary delays.

Moreover, regular maintenance of pressers is essential. A well-maintained machine can operate more efficiently, resulting in better product consistency. Unfortunately, some facilities neglect this, causing increased wear and tear. According to a survey, about 30% of manufacturers reported equipment failure due to inadequate maintenance. Reflecting on these practices can enhance production quality and output significantly.

Best Tablet Pressers for Efficient Production in 2026

| Dimension | Description | Efficiency Rating | Max Output (tablets/min) | Operation Type |

|---|---|---|---|---|

| Compression Force | Maximum force exerted during tablet production | High | 500 | Automatic |

| Die Size | Diameter of the tablet die used in the press | Moderate | 250 | Semi-Automatic |

| Tablet Thickness | Maximum thickness of the tablets produced | High | 300 | Manual |

| Production Speed | Speed of tablet production per unit time | Excellent | 700 | Automatic |

| Ease of Cleaning | How easy it is to clean the equipment | Good | N/A | Semi-Automatic |

Future Trends in Tablet Pressing: What to Expect Beyond 2026

As we look ahead to 2026, the landscape of tablet pressing is set to evolve significantly. Automation will play a vital role. Machines will become smarter, optimizing production in real-time. This shift could streamline operations and reduce human error. Manufacturers may invest in technologies that enhance precision. However, will they sacrifice quality for speed? This is a question worth pondering.

Sustainability will also be a major focus. Materials used in tablet production may become more eco-friendly. The industry might see a rise in biodegradable options. This change is promising but presents challenges. Transitioning to new materials could complicate the manufacturing process. Training workers on these new methods may require time and resources.

Innovation is not without its drawbacks. Increased reliance on technology may lead to significant job displacement. Workers must adapt to new roles as machines gain ground. The balance between efficiency and employment will be crucial. The future of tablet pressing must address these pressing issues. Engaging with this dynamic environment will be essential for success.

Related Posts

-

How to Use a Tablet Presser for Effective Tablet Making Techniques

-

How the Best Tablets Press Machine is Shaping the 2025 Industry Tech Landscape

-

How to Optimize Your Production Efficiency with a Tablet Presser for Maximum Yield

-

Ultimate Guide to Choosing the Best Tablets Press Machine for Your Production Needs

-

How to Choose the Right Tablets Press Machine for Your Production Needs

-

Ultimate Guide to Selecting the Right Tablets Press Machine Tips for Success