Blog

What is the Best Tablets Press Machine for Your Needs?

Choosing the right Tablets Press Machine can be daunting. Different manufacturers offer various models, each with unique features. According to Dr. Emily Carter, a leading expert in pharmaceutical manufacturing, "Selecting the right machine is critical for efficiency and product quality."

When evaluating a Tablets Press Machine, consider factors like production capacity and ease of use. Some machines are capable of producing thousands of tablets per hour. Others may have intricate controls that require specialized training. Both aspects impact the overall workflow.

It's crucial to reflect on your specific needs. For instance, a small-scale operation might benefit from a manual machine, while large facilities often need high-speed automatic options. Quality should not be compromised. Finding the right balance between speed and precision is essential. The right Tablets Press Machine makes a significant difference in your production line efficiency.

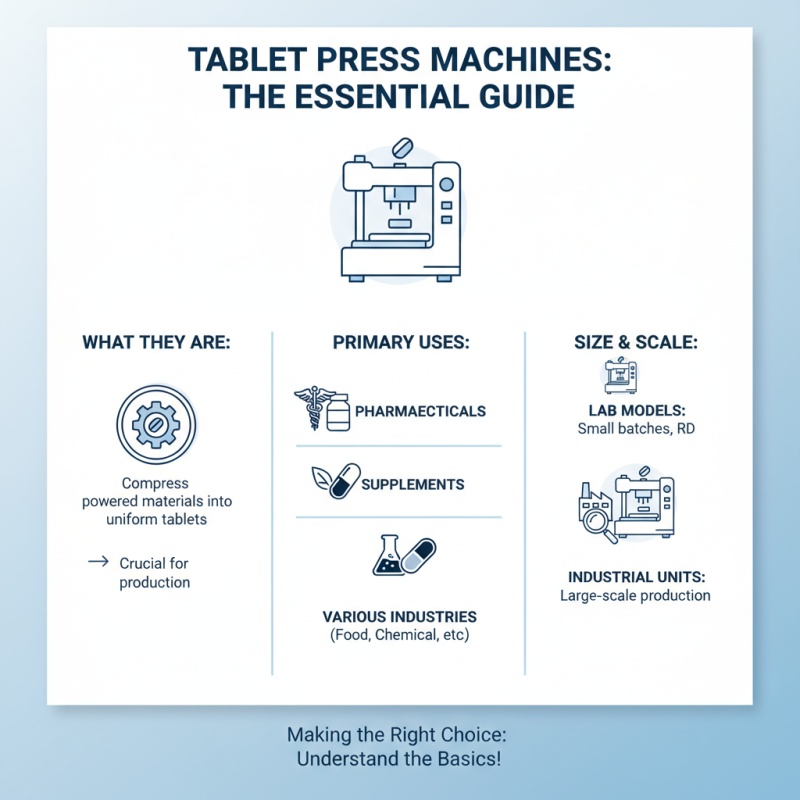

Understanding the Basics of Tablet Press Machines

Tablet press machines are essential for creating tablets in various industries. Understanding their basics is key to making the right choice. These machines compress powdered materials into tablets, making them suitable for pharmaceuticals, supplements, and more. They come in different sizes, from small laboratory models to large industrial units.

When selecting a tablet press machine, consider your production volume. A small lab may only require a manual machine. However, large-scale operations need automatic models for efficiency. Look at features like die sizes and compression force. They affect tablet quality and production speed.

Tips: Always analyze the materials you use. Some powders flow better than others. This affects compression and tablet consistency. Regular maintenance is also necessary. A neglected machine can lead to inconsistencies. Be prepared to make adjustments. Test different settings to find optimal results.

Key Features to Consider in a Tablet Press Machine

When selecting a tablet press machine, certain features are crucial. The most important is the press capacity. A larger capacity means the machine can produce more tablets in less time. However, more power may also lead to uneven tablet formation. Balancing capacity and quality is vital.

Another key feature is the control system. A user-friendly interface makes operation easier. Modern machines may have touchscreens and programmable settings. But too many settings can confuse operators. Striking the right balance is essential for efficiency.

Material compatibility is also significant. Not all machines can handle every type of formulation. Some may require specific materials that increase costs. These factors are often overlooked yet can affect overall production. Make sure to evaluate your specific needs carefully.

Types of Tablet Press Machines and Their Applications

When choosing a tablet press machine, consider its types and applications. There are multiple types of tablet presses, each with distinct functions. Single-station presses are often suitable for small-scale production. They are easy to operate and ideal for research and development environments. Conversely, rotary tablet presses are designed for high-volume production. They can produce thousands of tablets per hour.

Tips: Assess your production needs carefully. This will guide you in selecting the right machine type. Don't overlook the importance of machine features like tooling flexibility and speed settings.

Understanding the application of each type is crucial. For example, pharmaceuticals require high precision and consistency. This may not be the case for dietary supplements. You might find some machines overly complex for simple products.

Tips: Always gauge the learning curve of new machines. Some operators may find them challenging initially. Investing time in training can save you headaches later on.

What is the Best Tablets Press Machine for Your Needs? - Types of Tablet Press Machines and Their Applications

| Type of Tablet Press Machine | Description | Applications | Production Capacity (Tablets/hour) |

|---|---|---|---|

| Single Punch Tablet Press | Basic machine for small-scale production. | Pharmaceuticals, Nutraceuticals | 1,000 - 3,000 |

| Rotary Tablet Press | High-speed, efficient production machine. | Pharmaceuticals, Food Industry | 10,000 - 100,000 |

| Multi-layer Tablet Press | Capable of producing tablets with multiple layers. | Advanced pharmaceuticals, Special formulations | 5,000 - 50,000 |

| Effervescent Tablet Press | Designed for producing effervescent tablets. | Pharmaceuticals, Dietary Supplements | 3,000 - 30,000 |

| Briquetting Machine | Used for compressing powder into briquettes. | Chemical, Mineral Processing | 2,000 - 20,000 |

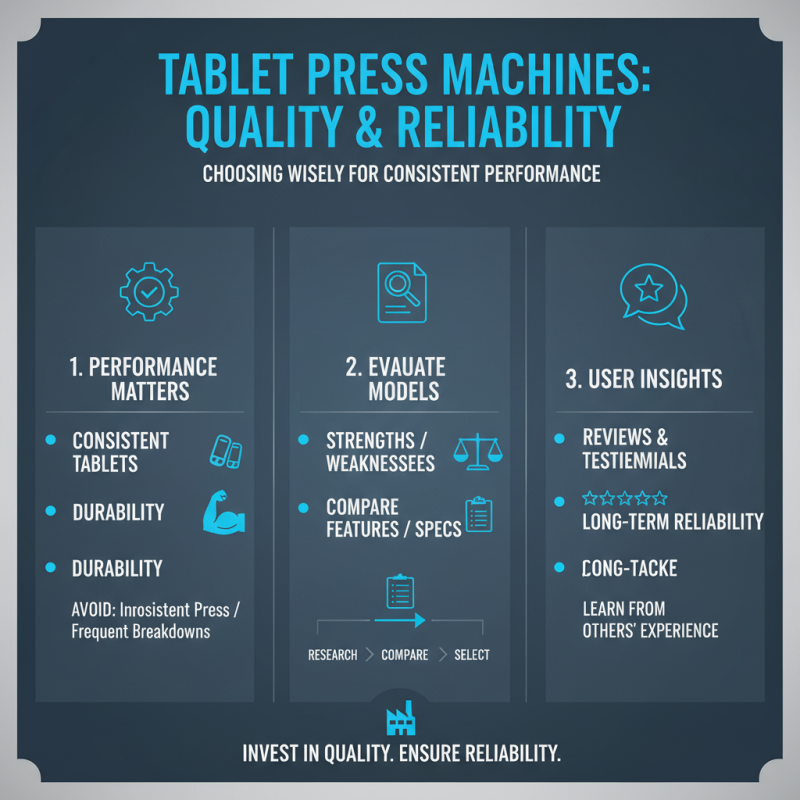

Evaluating Brands and Models for Quality and Reliability

When choosing a tablets press machine, quality and reliability are paramount. Not all machines offer the same level of performance. A careful evaluation of various models can reveal their strengths and weaknesses. Some may produce inconsistently pressed tablets, while others might struggle with durability. It's critical to analyze user reviews and testimonials for insights on how machines perform over time.

Many brands present numerous options, but not all of them meet the necessary standards. Some seem to emphasize flash over function. Just because a model looks good doesn’t mean it works well. Consider machines that have a proven track record. Look for those with robust support and a history of reliability, as this is often a sign of a well-made product.

Paying attention to features can also guide your choice. Adjustable settings, for example, are crucial for different tablet sizes. Machines with user-friendly interfaces tend to have better user experiences. However, sometimes the most expensive models may not be the best fit for everyone. Reflecting on your specific needs can help you avoid potential pitfalls in your purchase. Always be ready to adapt your choice based on thorough research and personal requirements.

Price Range and Budgeting for Your Tablet Press Needs

When choosing a tablet press machine, budgeting is crucial. Prices vary widely based on features and capabilities. Entry-level models can start around $5,000, while advanced machines may exceed $50,000. This range reflects different needs in the pharmaceutical and supplement industries. Each application may require different specifications, affecting the choice of equipment.

Consider your production goals. If you expect high volume, investing in a robust machine is vital. Data suggests that larger operations may require equipment capable of producing thousands of tablets per hour. If your needs are smaller, a basic model might suffice. Industry reports indicate that businesses often overlook maintenance costs, which can add up.

Tip: Always factor in long-term expenses. A cheaper machine may require more repairs, impacting your budget. Look for models with a good track record to avoid future regrets. Additionally, assess the training needed for operators. This often gets underestimated, impacting overall efficiency. Make a checklist of your must-have features and stick to it.

Cost Comparison of Different Tablet Press Machines

Related Posts

-

Why Choose Natoli Tablet Press for Your Pharmaceutical Manufacturing Needs

-

A Comprehensive Guide to the Best Tablet Presses for Global Buyers

-

Mastering Natoli Tablet Press Techniques for Optimal Performance

-

How to Optimize Your Production Efficiency with a Tablet Presser for Maximum Yield

-

How to Optimize Tablet Presser Efficiency with Data Driven Insights on Compression Techniques

-

How to Optimize Your Manufacturing Process with a Tablet Presser