Blog

Unlocking Efficiency: The Ultimate Guide to Capsule Filling Plates for Optimal Productivity

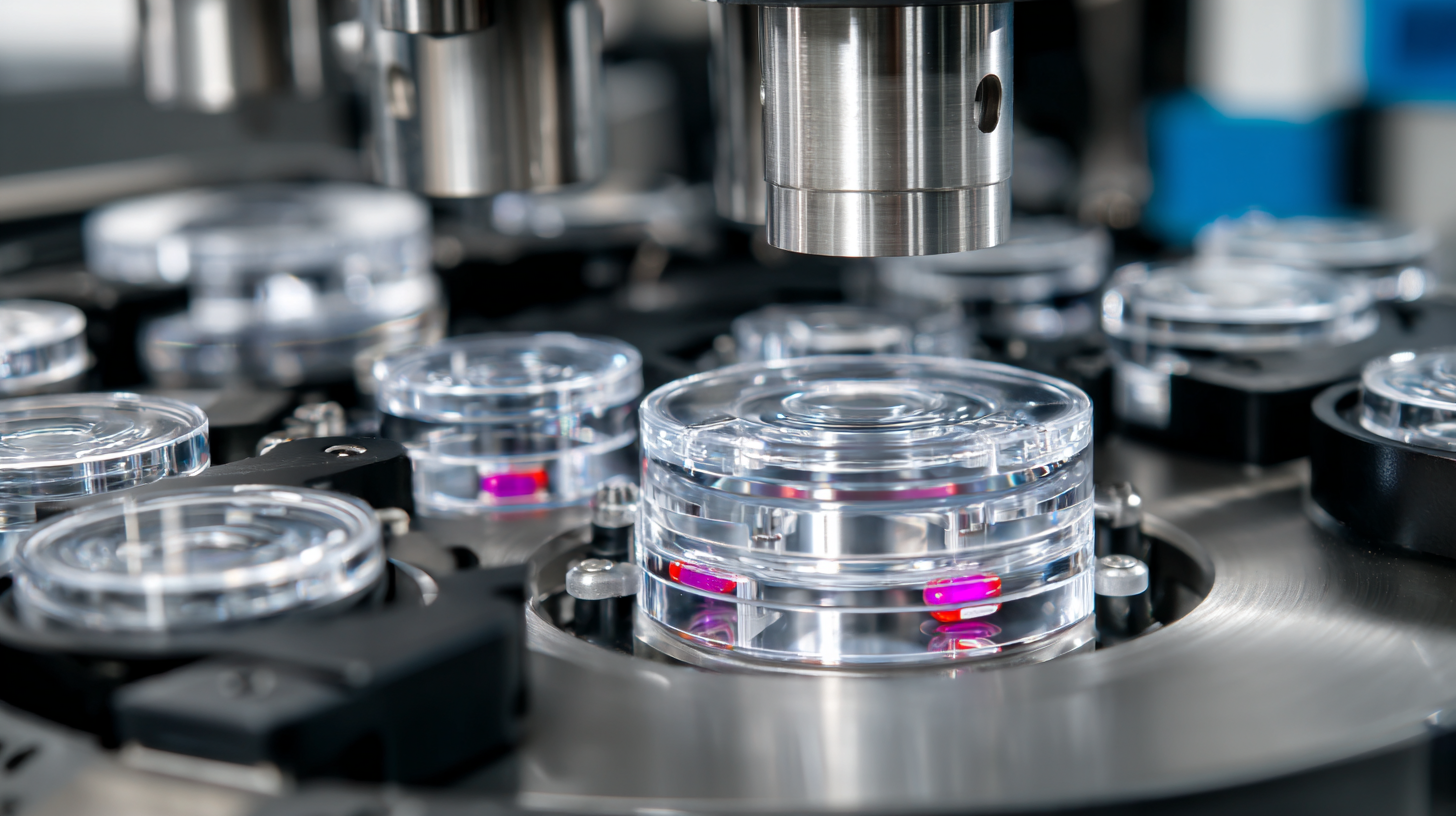

In today's fast-paced pharmaceutical and nutraceutical industries, achieving optimal productivity is crucial for staying competitive. According to a recent report by Grand View Research, the global capsule filling equipment market is projected to reach $1.6 billion by 2025, demonstrating an increasing demand for efficient processes that streamline production. One essential tool in this arena is the Capsule Filling Plate, which significantly enhances the accuracy and efficiency of filling capsules with various formulations. By incorporating the right Capsule Filling Plate into their manufacturing process, companies can reduce the likelihood of errors, minimize waste, and boost overall output. This ultimate guide aims to unlock the potential of Capsule Filling Plates, providing insights on how to select and utilize these vital tools for maximum efficiency and productivity in capsule filling operations.

Understanding Capsule Filling Plates: Types and Their Applications

Capsule filling plates are essential tools in the pharmaceutical and dietary supplement industries,

allowing for efficient and precise filling of capsules. There are several types of capsule filling plates,

each designed to cater to specific needs. For instance, manual filling plates are suitable for small-scale operations,

providing an affordable and straightforward solution for those who need to fill capsules without expensive machinery. These plates often come in

various sizes to accommodate different capsule types, making them versatile options for diverse formulations.

In contrast, automatic capsule filling plates offer a higher level of efficiency

and are ideal for larger production environments. These machines can fill thousands of capsules per hour, significantly enhancing productivity.

Additionally, automatic filling plates can be programmed for various capsule sizes and filling materials, allowing for seamless adjustments between different products.

Both manual and automatic options play crucial roles in optimizing capsule filling processes, ensuring that businesses can meet their production goals while maintaining

high standards of quality and accuracy in their products.

The Science Behind Capsule Filling: Efficiency and Speed Metrics

Capsule filling technology has evolved significantly, emphasizing the importance of efficiency and speed in production. The core of this advancement lies in understanding the science behind capsule filling plates. These specialized tools enable the precise and rapid filling of capsules, minimizing downtime and maximizing output. Key metrics such as fill time per capsule, the consistency of weight distribution, and the rate of capsule ejection are foundational in evaluating the efficiency of different filling systems.

Moreover, the design and material of the filling plates play a critical role in the operational speed. Innovations in ergonomics and automation have led to the development of plates that not only streamline the filling process but also maintain a high level of accuracy in dosage. By analyzing speed metrics, manufacturers can identify bottlenecks in their processes and implement solutions tailored to enhance productivity. The synergy between advanced technology and effective design principles ultimately paves the way for superior performance in capsule production, making it essential for businesses to adopt these advancements to remain competitive.

Assessing Material Choices: Impact on Durability and Productivity

When selecting capsule filling plates, the choice of materials plays a crucial role in both durability and productivity. Common materials include stainless steel, plastic, and silicone, each bringing unique advantages and limitations. Stainless steel plates offer exceptional longevity and resistance to wear, making them ideal for high-volume environments where frequent usage is the norm. Their robust nature ensures that they maintain structural integrity over time, which directly influences the overall efficiency of the capsule production process.

On the other hand, plastic filling plates are often favored for their lightweight nature and cost-effectiveness. While they may not match the durability of stainless steel, advancements in plastic technology have led to the development of high-performance composites that can withstand repeated use. However, users should consider the potential for wear and tear in more demanding settings. Silicone plates offer a different set of benefits, including flexibility and ease of cleaning. Their non-stick properties can enhance productivity by reducing the time spent on maintenance, yet they may not provide the same longevity as their metal counterparts. Ultimately, understanding the impact of material choices on durability is essential for optimizing productivity in capsule filling operations.

Industry Standards and Compliance: Ensuring Quality in Capsule Production

In the rapidly evolving industry of capsule production, adhering to established standards and compliance regulations is essential for ensuring product quality and safety. Manufacturers must navigate a complex landscape of guidelines set forth by organizations such as the FDA and ISO, which outline best practices in the production process. This includes everything from material selection and production techniques to quality control measures that maintain the integrity of the final product. Emphasizing these standards not only enhances the reputation of a company but also protects consumers by minimizing the risk of contamination and ensuring that capsules meet the necessary efficacy requirements.

Implementing robust compliance protocols can also lead to increased operational efficiency. By regularly auditing processes and training personnel on industry standards, manufacturers can identify areas for improvement and streamline their production workflows. For instance, employing capsule filling plates that are designed according to compliance requirements can significantly reduce the risk of errors during the filling process, thus optimizing productivity. Additionally, investing in technology that allows for real-time monitoring of production conditions can help ensure adherence to quality benchmarks, ultimately fostering a culture of excellence that benefits both the company and its customers.

Unlocking Efficiency: The Ultimate Guide to Capsule Filling Plates for Optimal Productivity

| Dimension | Value | Notes |

|---|---|---|

| Plate Size | 20cm x 30cm | Standard size for most capsule types. |

| Material | Polycarbonate | Durable and easy to clean. |

| Weight | 1.5 kg | Lightweight for ease of handling. |

| Compatibility | Sizes 00, 0, 1 | Compatible with major capsule sizes. |

| Production Rate | 3000 capsules/hour | High efficiency for large batches. |

| Compliance Standards | cGMP | Complies with current Good Manufacturing Practices. |

Future Trends in Capsule Filling Technology: Innovations Driving Efficiency

The landscape of capsule filling technology is rapidly evolving, driven by innovations designed to enhance efficiency and productivity in pharmaceutical and nutraceutical industries. As the demand for customized formulations rises, manufacturers are adopting advanced capsule filling plates that streamline the production process. These innovations not only optimize filling speeds but also reduce waste, ensuring a more sustainable approach to encapsulation.

One of the most significant trends is the integration of automation in capsule filling systems. Smart technologies, including AI-powered data analytics and robotics, enable real-time monitoring and adjustment of the filling process. This results in higher precision and reduced error rates, allowing for scalable production without compromising on quality. Additionally, the development of specialized materials for filling plates is further enhancing their durability and performance, paving the way for more efficient and cost-effective manufacturing solutions.

As these advancements continue to unfold, the future of capsule filling technology promises a noteworthy shift towards enhanced operational efficiencies and customized product offerings.

Related Posts

-

Ultimate Guide to Choosing the Best Capsule Filling Plate for Your Needs

-

Ultimate Checklist for Selecting the Right Capsule Loader Machine for Your Production Needs

-

Elevating Manufacturing Standards with the Best Capsule Loader Machine

-

Ultimate Guide to Efficient Capsule Loader Machine Solutions for Your Production Needs

-

Top Strategies for Optimizing Your Capsule Loader Machine Procurement Process

-

Common Issues Faced by Businesses When Choosing Capsule Packaging Machines