Blog

How to Choose the Best Blister Packing Machine for Your Needs?

Choosing the right Blister Packing Machine can be daunting. Expert Jane Doe, a leader in packaging technology, once said, "The right machine can transform your production line." This insight is crucial in today’s competitive market.

A Blister Packing Machine plays a vital role in protecting products. It ensures quality and enhances shelf life. However, not every machine is suitable for all products. Understanding specific needs is key.

Many companies overlook crucial factors. They focus solely on price, ignoring quality and performance. It's essential to evaluate the machine's capacity, speed, and ease of operation. Careful consideration will lead to better choices. Balancing budget and functionality is a fine line to walk.

Understanding Blister Packing Machines and Their Purpose

Blister packing machines are essential in various industries. They efficiently package products in a sealed format. This type of packaging offers protection against environmental factors. The machines are commonly used for pharmaceuticals, electronics, and consumer goods. Their main purpose is to secure items, prolong shelf life, and enhance presentation.

Choosing the right blister packing machine requires understanding specific needs. Not all machines are the same. Some may be ideal for small batches, while others suit larger production runs. It’s crucial to assess production capacity, material types, and product dimensions. Users often overlook the machine's efficiency. A slow machine can create bottlenecks. Instead, one might need a machine that adapts to varying production scales.

Consider your budget and maintenance requirements. A low-cost machine may lead to higher repairs over time. Investing in higher quality may seem daunting. However, reflect on the long-term savings. Choosing the wrong machine might waste resources. It's important to ask questions and seek advice. Every detail matters in this decision-making process.

Key Factors to Consider When Selecting a Blister Packing Machine

Choosing the right blister packing machine involves several critical factors. First, assess the production speed required for your operations. According to industry reports, machines can offer speeds ranging from 30 to over 300 cycles per minute. Evaluating your production volume is essential. If demand fluctuates, a machine with adjustable speeds might be beneficial.

Another key aspect is the type of product to be packed. Different materials, such as PVC, PVDC, or aluminum, may require specific machine features. Some machines handle a variety of materials, while others specialize. Researching the compatibility of your product with the machine is vital.

Tips: Consider the footprint of the machine. Space can be limited in packaging areas. A compact design may fit better in your facility.

Also, evaluate features like user-friendliness and ease of maintenance. Complicated setups can slow production. Careful consideration of your team's expertise may prevent future issues. A machine that is difficult to operate can lead to inefficiencies. Look for machines that offer training resources to aid your staff.

Ultimately, reflection on your long-term needs is important. Changes in regulations or market demands can affect your choice. Engaging in thorough research and possibly seeking input from industry peers can provide valuable insights. Balancing speed, material compatibility, and ease of use will help you make a more informed choice.

Analyzing Production Capacity and Efficiency Requirements

When selecting a blister packing machine, understanding production capacity and efficiency requirements is crucial. Industry studies suggest that a machine’s efficiency can greatly influence output. For instance, a well-optimized blister packaging line should ideally maintain an efficiency rate exceeding 80%. If your production goals aim for 100,000 units per month, you need to ensure your chosen machine can handle around 125,000 units to account for downtime and other inefficiencies.

Another critical aspect is the speed of the machine. Many machines can operate at 30 to 100 cycles per minute. However, some manufacturers overlook the importance of cycle accuracy. A machine that operates swiftly but delivers inconsistent results can lead to wastage. According to a recent report, nearly 15% of production losses stem from machine misalignment and product waste. Therefore, balancing speed with precision is essential.

Lastly, consider the flexibility of the machine in handling different product sizes and formats. Many companies face difficulties when scaling up or down production. A versatile machine that adapts quickly is vital. It's easy to underestimate the complexity of production needs. Relying solely on machine specs without aligning them with your specific requirements can create future challenges. Proper analysis and thoughtful consideration can lead to better choices.

Evaluating Budget Constraints and Cost-Effectiveness

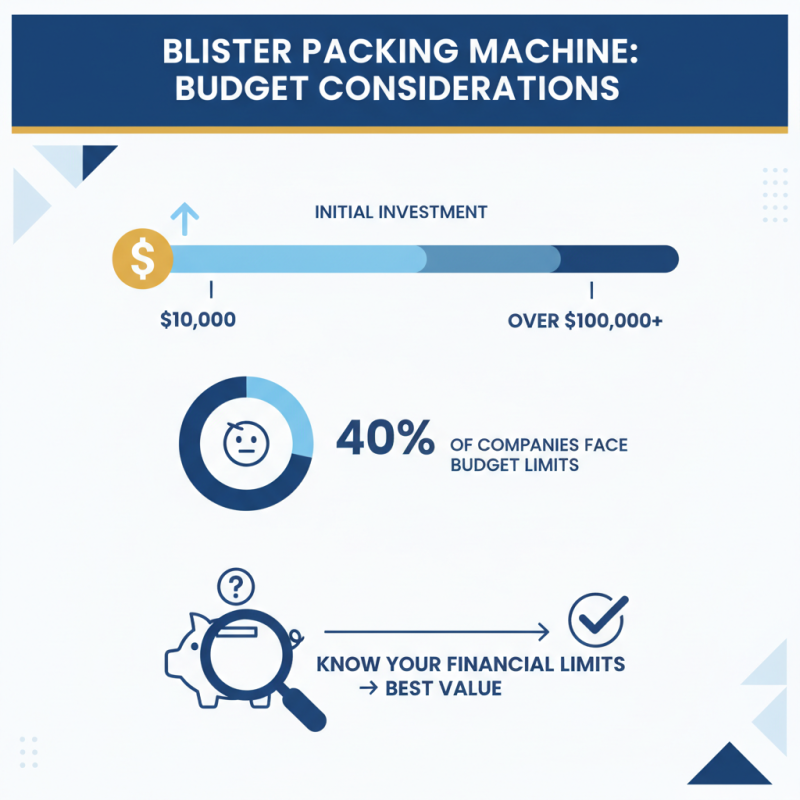

When selecting a blister packing machine, budget constraints are a critical factor. The initial investment can vary significantly, often ranging from $10,000 to over $100,000, depending on features and capacity. A recent industry report indicates that about 40% of companies cite budget limitations as a major challenge when acquiring packaging equipment. Therefore, understanding your financial limits can direct your search toward machines that deliver the best value.

Cost-effectiveness goes beyond the purchase price. Operational costs play a vital role, too. For instance, energy-efficient machines might have a higher upfront cost but can save significant amounts on electricity over time. According to a study, companies reported saving up to 25% annually on energy by investing in modern, efficient machines. Maintenance costs also need consideration. Some machines require fewer repairs and offer longer lifespans, alleviating long-term expenses. Reflecting on these aspects can lead companies to better decisions.

Choosing a blister packing machine is not a straightforward task. Mistakes often occur when companies overlook total cost factors. Inadequate research might lead to overspending or acquiring machinery that doesn't meet specific needs. Industry insights frequently emphasize the importance of evaluating all costs, not just the initial price, to ensure a favorable return on investment.

Assessing the Technical Support and Maintenance Services Available

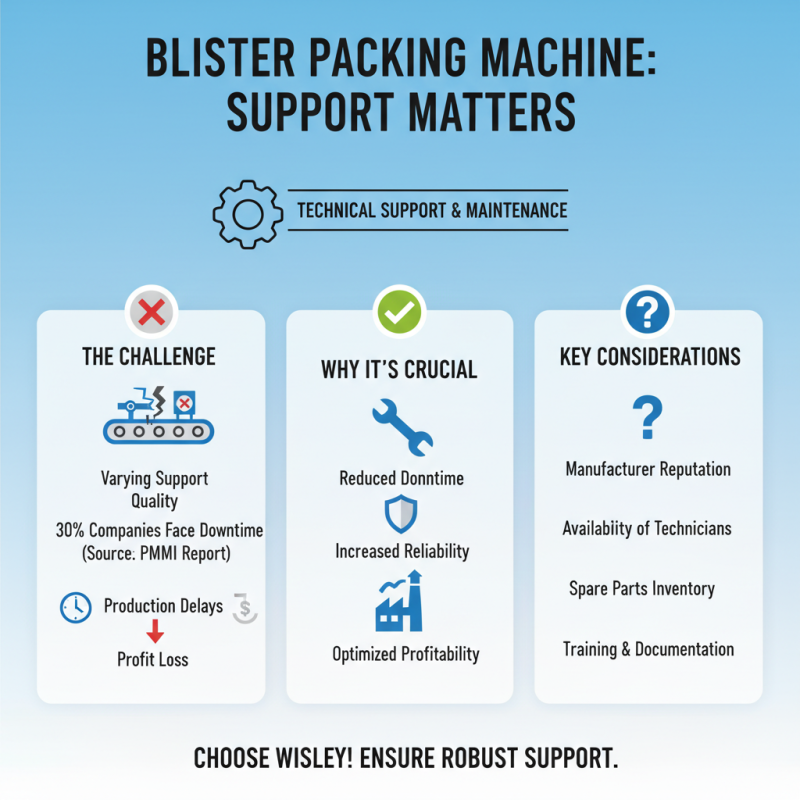

When selecting a blister packing machine, assessing technical support and maintenance services is crucial. Many manufacturers offer support, but the quality varies widely. According to a report by the Packaging Machinery Manufacturers Institute, around 30% of companies face downtime due to inadequate support. This has tangible impacts on production schedules and profitability.

Look for suppliers with robust technical assistance. Ensure they provide rapid response times. Industry standards suggest that ideal response time should be within four hours. Additionally, focus on the availability of spare parts. It reduces downtime significantly. Many organizations experienced a 20% increase in efficiency after ensuring easy access to components.

Consider ongoing maintenance services as well. Regular maintenance can extend your machine's lifespan. Research has shown that machines with scheduled maintenance have 40% fewer breakdowns. While initial costs may be higher, the long-term benefits can be substantial. Reflect on the balance between upfront costs and future savings—this is essential for a sustainable operation.

Related Posts

-

Why You Should Consider Upgrading to a Modern Blister Packing Machine for Your Business

-

The Ultimate Guide to Blister Packing Machines: Benefits, Types, and Uses

-

Top Strategies for Enhancing Efficiency with Blister Packing Machines in Pharmaceutical Manufacturing

-

Challenges in Selecting the Right Blister Packing Machine for Your Production Needs

-

7 Best Blister Machine Pharma Innovations Enhancing Efficiency and Quality

-

How to Effectively Utilize Oral Thin Film Pouching for Enhanced Product Distribution