Blog

Elevating Manufacturing Standards with the Best Capsule Loader Machine

In the fast-evolving landscape of the manufacturing industry, the importance of efficiency and precision cannot be overstated. According to a recent report by the International Federation of Robotics, the adoption of automation in manufacturing processes has increased productivity by up to 30% in the last five years. A pivotal component in achieving this efficiency is the Capsule Loader Machine, which streamlines the production of various pharmaceutical and nutraceutical products. By integrating advanced technology with efficient design, these machines are helping manufacturers meet stringent regulatory standards while maximizing output.

Furthermore, a study by Market Research Future predicts that the global capsule filling machine market will grow substantially, fueled by rising demand for dietary supplements and personalized medicine. As manufacturers look to elevate their operations and maintain a competitive edge, investing in the best Capsule Loader Machine is not just a strategic move, but a necessity for future success.

The Significance of High-Quality Capsule Loader Machines in Modern Manufacturing

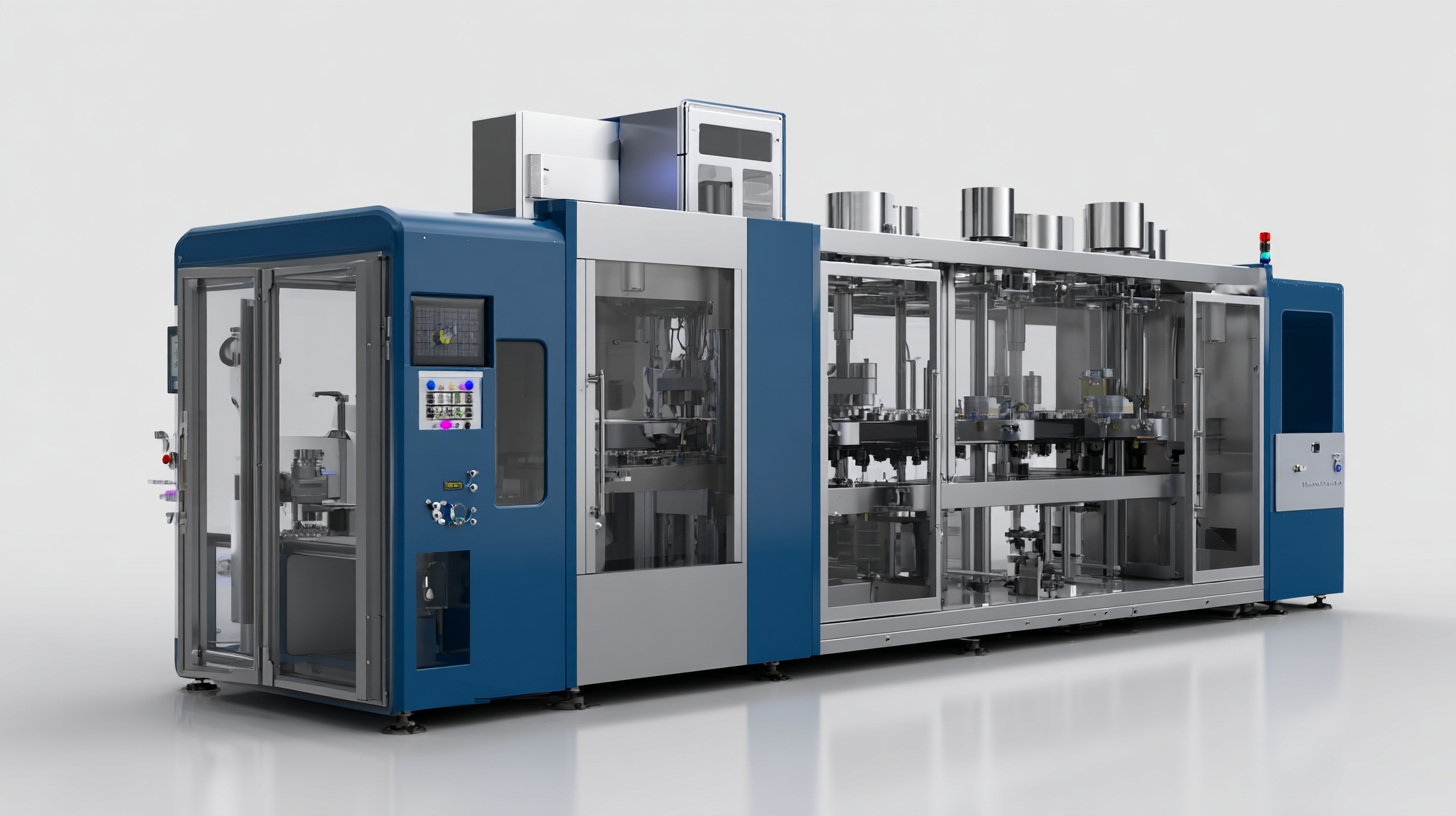

In today's fast-paced manufacturing environment, high-quality capsule loader machines play a pivotal role in ensuring efficiency and precision. These machines are designed to automate the process of filling and loading capsules, significantly reducing the time and labor associated with manual methods. With the growing demand for supplements and pharmaceuticals, the need for reliable capsule loading technology is paramount. A well-engineered capsule loader not only enhances productivity but also maintains the integrity of the product, minimizing the risk of contamination.

Furthermore, investing in advanced capsule loader machines can lead to significant cost savings in the long run. High-quality equipment ensures consistent performance, reducing maintenance needs and downtime. As manufacturers increasingly prioritize quality assurance, the use of state-of-the-art capsule loaders contributes to better compliance with industry standards and regulations. By elevating manufacturing processes with superior machines, companies can foster innovation and adapt more swiftly to changing market demands, ultimately leading to greater success in their respective industries.

Key Features That Make a Capsule Loader Machine Stand Out in the Market

When it comes to pharmaceutical manufacturing, the efficiency and precision of encapsulation processes are paramount. A top-tier capsule loader machine can significantly enhance productivity while ensuring optimum quality. Key features that make a capsule loader stand out include its automation capabilities, which allow for seamless integration into existing production lines. Automation not only reduces human error but also expedites the loading process, enabling manufacturers to meet high demand without compromising on standards.

Another vital feature is the machine's adaptability to different capsule sizes and formulations. A versatile capsule loader can handle a variety of capsules, from standard gelatin to vegetarian options, giving manufacturers flexibility in their product offerings. Additionally, advanced user interfaces with intuitive controls simplify operation and maintenance, ensuring that workers can efficiently monitor the loading process. These features, combined with robust construction and consistent performance, make certain capsule loader machines indispensable in the quest to elevate manufacturing standards in the competitive market.

How Chinese Manufacturing Excellence Sets a Global Standard for Capsule Loaders

Chinese manufacturing has long been recognized for its efficiency and innovation, particularly in the production of capsule loader machines. According to a recent report by MarketsandMarkets, the global capsule filling machine market is expected to reach USD 1.1 billion by 2025, driven largely by the advancements in manufacturing technology in China. These machines enhance productivity, providing precision and reliability, which are essential for pharmaceutical and nutraceutical companies looking to meet rising consumer demands.

**Tip:** When selecting a capsule loader, consider investing in equipment that offers automation capabilities to streamline your production process. This not only reduces labor costs but also minimizes the risk of human error, ensuring higher product quality.

Moreover, the emphasis on sustainability within Chinese manufacturing has further elevated industry standards. Research from the China National Chemical Information Center shows that manufacturers are increasingly adopting eco-friendly practices, contributing to a greener production landscape. By aligning with these standards, businesses can not only improve their operational efficiencies but also enhance their brand reputation globally.

**Tip:** Ensure that your capsule loader machine complies with international quality standards such as ISO and cGMP. This ensures that your production processes meet the necessary regulatory requirements, giving you an edge in global markets.

Maximizing Efficiency: The Role of Advanced Technology in Capsule Loading

In the rapidly evolving world of manufacturing, the significance of advanced technology in capsule loading cannot be overstated. As industries strive for higher efficiency and minimized production costs, capsule loader machines equipped with cutting-edge technology are revolutionizing the way products are packaged. These machines incorporate features such as automated sorting, precise filling mechanisms, and real-time monitoring systems, which substantially streamline the loading process and reduce manual labor.

Furthermore, the integration of smart technology ensures optimal performance and flexibility in production lines. By utilizing data analytics and machine learning algorithms, modern capsule loaders can adapt to varying production demands and identify potential issues before they escalate. This proactive approach not only enhances productivity but also improves quality control, ensuring that each capsule is filled accurately and consistently. As manufacturers embrace these advancements, they are well-positioned to meet the challenges of a competitive market while delivering superior products that meet the highest standards of quality.

Efficiency of Capsule Loader Machines

Ensuring Consistency and Quality Control with Reliable Capsule Loader Machines

In the fast-paced world of manufacturing, ensuring consistency and quality control is paramount. Reliable capsule loader machines play a crucial role in this process, as they streamline production while maintaining the integrity of each capsule. By investing in high-quality machinery, manufacturers can significantly reduce variability and bolster their reputation for quality.

One tip for achieving superior results is to ensure regular maintenance of the capsule loader machine. Routine checks not only prolong the machine's lifespan but also prevent unexpected downtime, which can disrupt the entire production line. Additionally, consider implementing a robust training program for operators. Knowledgeable staff can effectively troubleshoot issues, further ensuring consistency during the loading process.

Another key factor is the selection of the right capsule loader machine for your specific needs. Different models offer varying capabilities, so it’s essential to assess production demands thoroughly. Look for machines that allow for adjustments in speed and filling volumes, enabling flexibility without sacrificing accuracy and quality in each batch produced. This attention to detail can lead to a smoother operation and improved end-product quality, making a significant difference in overall manufacturing standards.