Blog

What is a Fluidized Bed Processor and How Does It Work?

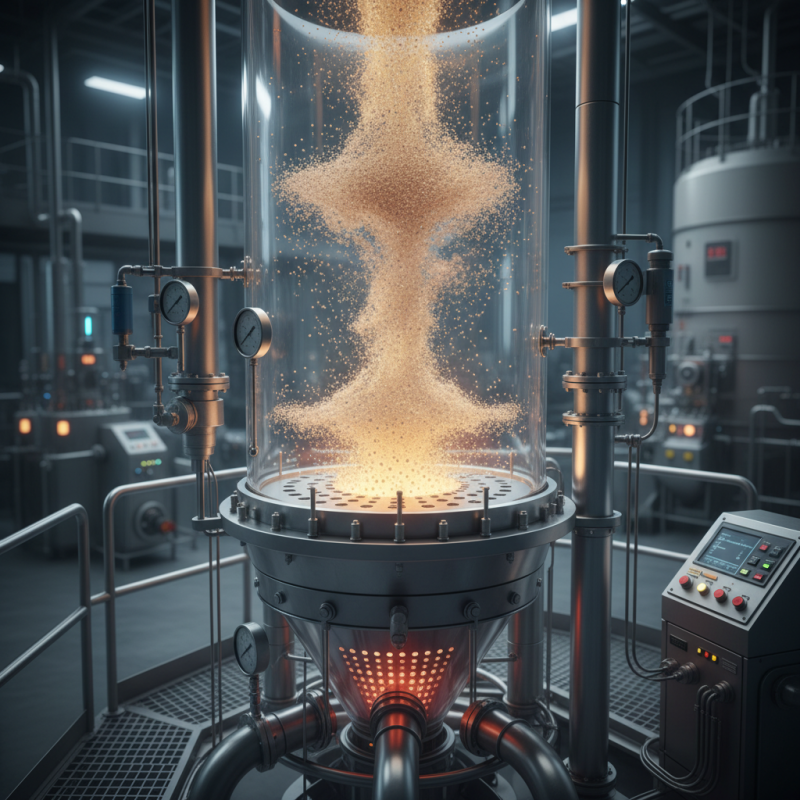

The Fluidized Bed Processor is a critical technology used in various industries. It allows for efficient mixing and heat transfer of particles. Dr. John Thompson, a leading expert in this field, states, "Fluidized bed technology can significantly enhance product uniformity and processing speed." This statement reflects the importance of understanding how these systems work.

Fluidized Bed Processors operate by suspending solid particles in a fluid. This creates a dynamic environment where heat and mass transfer occurs efficiently. The design of these systems can be complex, but their applications are vast. They are utilized in pharmaceutical production, food processing, and materials engineering. However, challenges such as particle size uniformity and equipment cost remain topics for further investigation.

Despite the benefits, there are pitfalls in using Fluidized Bed Processors. Operators must monitor conditions closely to avoid issues like particle agglomeration. This requires expert knowledge and experience in the field. Striking a balance between automation and manual oversight is crucial. Continued research and dialogue among professionals in the industry can lead to better solutions and advancements.

What is a Fluidized Bed Processor? A Comprehensive Definition

A fluidized bed processor is an efficient system used for various industrial processes. It consists of a bed of solid particles that are suspended in an upward-flowing gas, typically air. This design creates a dynamic environment where heat and mass transfer occur more effectively. The fluidization allows the particles to behave like a liquid, enhancing the mixing and reaction rates.

In a fluidized bed, particles can vary in size and density. This variability can influence the system's performance.

Operators need to pay attention to parameters like airflow and particle characteristics. Ideally, the process should enable uniform distribution and reaction of ingredients. However, achieving this balance can be challenging. Sometimes, uneven fluidization can lead to clumping or channeling, which reduces efficiency.

Understanding a fluidized bed processor is crucial for optimizing its use. While it offers many advantages, successful operation requires careful monitoring and adjustment. For example, changes in feed composition can impact the desired outcome. Regular reflections on the system's performance are essential to address any discrepancies.

It's a continuous learning process, requiring operators to adapt and refine their strategies over time.

Principles of Fluidization: Key Concepts and Mechanisms

Fluidization is a fascinating phenomenon widely applied in various industries. It occurs when a solid material behaves like a fluid while air or another gas flows through it. This process transforms solid particles into a bubbling, moving bed. The key concept here is the balance between gravitational and drag forces. When the drag force from the gas exceeds the weight of the particles, fluidization occurs.

Several mechanisms drive this process. One is the formation of bubbles within the bed, which influences the flow of particles. The size and distribution of particles affect how effectively they fluidize. Smaller particles tend to fluidize more easily due to their greater surface area. However, larger particles may cause uneven fluidization, leading to chaotic behavior. Sometimes, this can even hinder the efficiency of the process.

Fluidized beds are sensitive to changes in flow rate and particle size. When these variables shift, the behavior of the bed can differ significantly. Operators need to monitor and adjust conditions constantly. This need for vigilance can sometimes lead to unexpected challenges. Balancing efficiency and stability is an art as much as it is a science in fluidization principles. Understanding these dynamics can enhance processing techniques in various fields.

Applications of Fluidized Bed Processing in Various Industries

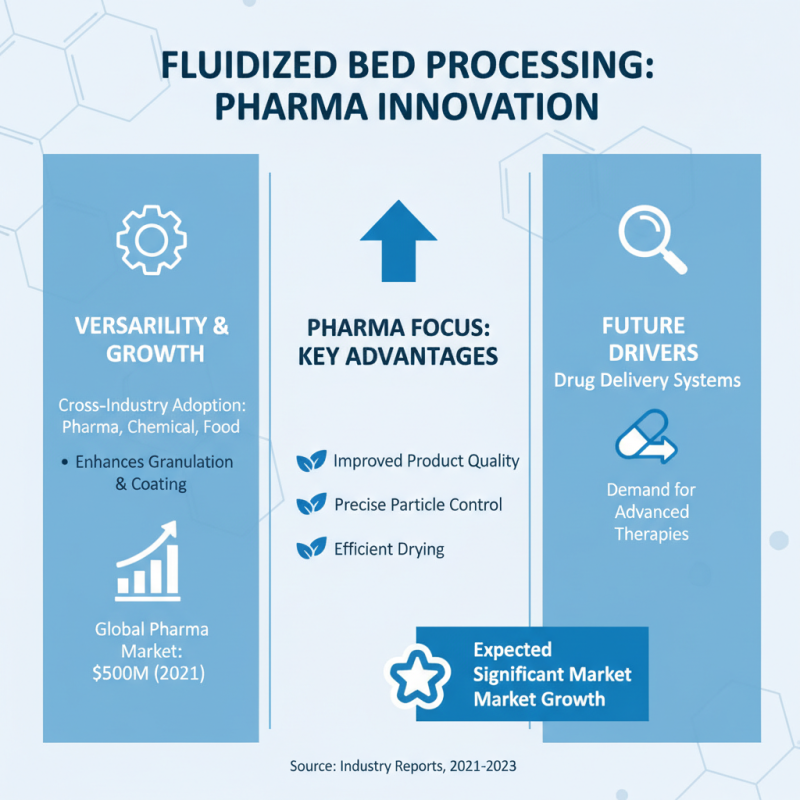

Fluidized bed processing is gaining traction across various industries due to its versatility. In pharmaceuticals, it enhances granulation and coating processes. The global pharmaceutical fluidized bed systems market was valued at approximately $500 million in 2021. This sector is expected to grow significantly, driven by the demand for targeted drug delivery systems.

In food processing, fluidized beds are used for drying and coating food products. This method ensures uniform distribution and temperature control, leading to better quality. The food processing industry is seeing a trend toward more efficient techniques, with the market for fluidized bed systems projected to grow by 8% annually through 2028. However, the technology isn’t flawless; challenges like scale-up can hinder performance consistency.

Chemical manufacturing also benefits from fluidized bed processors. They provide efficient mixing and heat transfer for catalytic reactions. The chemical sector relies on these systems to minimize energy consumption and maximize output. Yet, improper operation can result in poor product quality or equipment damage. This highlights the importance of training and process control in this area.

Efficiency Metrics: Performance Data and Comparisons

Fluidized bed processors have become essential in various industries due to their efficiency and versatility. According to a report from the International Journal of Chemical Engineering, these systems can achieve a drug release rate of over 90% within the first hour. This stands in stark contrast to traditional methods, which often yield rates closer to 70%. The ability to maintain a consistent particle suspension enhances heat and mass transfer, resulting in better product uniformity.

However, operational challenges remain. Fluidization quality can fluctuate based on the physical properties of the particles being processed. Studies have indicated that discrepancies in particle size can lead to non-uniform fluidization. A performance evaluation conducted in 2022 revealed that 15% of fluidized bed operations experienced instability under variable loading conditions. Such data highlights the need for constant monitoring to improve system efficiency.

In terms of energy consumption, fluidized bed processors are shown to be more energy-efficient than traditional batch systems. A comparative analysis published in the Chemical Engineering Journal indicated that these processors can reduce energy consumption by up to 25% for similar throughput levels. Despite these advantages, the initial setup costs can be higher, prompting companies to weigh long-term savings against upfront investments.

Fluidized Bed Processor Efficiency Metrics

Environmental Impact and Sustainability of Fluidized Bed Systems

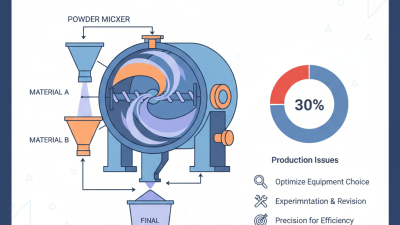

Fluidized bed systems have gained popularity due to their efficiency and potential sustainability benefits. These systems operate by suspending solid particles in an upward flow of gas. This process enhances mixing and heat transfer. Studies suggest that fluidized beds can reduce energy consumption by up to 30% compared to traditional combustion methods.

The environmental impact of these systems is significant. Fluidized beds can efficiently utilize low-grade fuels, thus lowering greenhouse gas emissions. According to the International Energy Agency, integrating fluidized bed technology could reduce carbon emissions by about 25% in power generation. However, the actual benefits depend on the feedstock used and the operational conditions.

**Tip:** Regular maintenance of fluidized bed systems is crucial. This ensures optimal performance and minimizes emissions. Operators should monitor fluidization quality closely. Maintaining proper temperatures and flow rates can maximize sustainability.

Despite these advantages, challenges remain. The efficiency can vary with different materials. Not all biomass can be processed effectively. Some feedstocks may lead to higher emissions. Operators must assess feedstock quality and compatibility with the system. Continuous research and adaptation are vital for improving these systems.

Related Posts

-

What is a Fluidized Bed Processor and How Does It Work for Efficient Material Processing?

-

10 Essential Tips for Understanding Cbd Monobloc Benefits and Uses

-

The Ultimate Guide to Powder Mixers Tips for Best Results

-

How to Effectively Use Oral Dispersible Tablets for Enhanced Patient Compliance and Drug Delivery

-

How to Choose the Right Capsules Filling Machine for Your Production Needs

-

Why Invest in a Syringe Assembly Machine for Your Manufacturing Needs