Blog

Ultimate Guide to Choosing the Best Tablets Press Machine for Your Production Needs

In today's competitive manufacturing landscape, selecting the right Tablets Press Machine is crucial for optimizing production efficiency and product quality. According to a recent industry report by Research and Markets, the global tablet press market is projected to grow at a CAGR of 6.5% from 2021 to 2026, driven by the increasing demand for pharmaceuticals and nutraceuticals. As businesses strive to enhance their production capabilities, understanding the various types and technologies of Tablets Press Machines becomes essential. From single-sided to multi-station presses, each type offers distinct advantages tailored to specific production needs. This guide aims to provide you with comprehensive insights into the selection process, taking into account current market trends and technological advancements, to ensure that your investment aligns with your operational goals and industry standards.

Understanding the Different Types of Tablets Press Machines Available on the Market

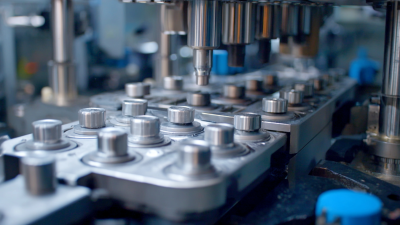

When selecting a tablet press machine, it is essential to understand the different types available on the market to match your production needs effectively. The primary categories include single-station press machines, which are suited for smaller operations or prototype batches, and multi-station press machines, which are designed for high-volume production. Single-station machines typically offer greater flexibility for varied tablet shapes and sizes, making them ideal for research and development phases or custom projects.

In contrast, multi-station tablet presses operate with multiple punches and dies, allowing for faster production rates and consistent output quality. They are favored in pharmaceutical and nutraceutical manufacturing due to their efficiency and reliability. Moreover, specialized tablet presses, such as rotary models, cater to specific needs by enhancing speed and maintaining precise tablet weight and hardness. Understanding these distinctions will significantly influence the decision-making process and ensure that the chosen equipment aligns with both current and future production demands.

Key Features to Look for in a High-Quality Tablets Press Machine

When selecting a high-quality tablet press machine, it's essential to focus on features that enhance both efficiency and production capability. One of the key aspects to consider is the machine's compression capability. According to a recent market report from Smithers Pira, the global tablet press market is expected to grow by 6.5% annually, indicating a rising demand for robust machines that can handle various formulations and maintain precise dosage control.

Another critical feature to look for is the machine's ease of use and maintenance. Modern tablet press machines come equipped with advanced control systems that simplify operation and reduce downtime. For example, systems with digital interfaces allow for real-time monitoring of pressing parameters, ensuring consistency and minimizing waste. A study by HAPPS (Hygienic and Accurate Pharmaceutical Production Systems) highlights that user-friendly machines can significantly decrease training time and improve overall production efficiency.

**Tip:** Always check for the availability of technical support and spare parts when choosing a tablet press machine. This can dramatically impact the longevity and performance of your equipment. Additionally, consider machines that comply with industry standards, as these will offer enhanced safety and reliability in production processes.

Ultimate Guide to Choosing the Best Tablets Press Machine for Your Production Needs - Key Features to Look for in a High-Quality Tablets Press Machine

| Feature | Description | Importance | Range/Options |

|---|---|---|---|

| Compression Force | The maximum force applied to compress the tablets. | Ensures proper tablet density and hardness. | 5 - 100 tons |

| Number of Stations | The number of dies available for tablet production. | Increases production efficiency. | 1 - 42 stations |

| Output Rate | The number of tablets produced per hour. | Determines production capacity. | 1,000 - 200,000 tablets/hour |

| Tablet Size | Range of sizes the machine can produce. | Flexibility in production. | 2 mm - 25 mm |

| Control System | Type of software and controls used. | Affects precision and ease of operation. | Manual, semi-automatic, fully automatic |

Evaluating Production Needs: Manual vs. Automatic Tablets Press Machines

When choosing the right tablet press machine, evaluating your production needs is paramount. Understanding the differences between manual and automatic tablet press machines can significantly impact your manufacturing efficiency and product quality.

Manual machines offer a more hands-on approach, allowing for greater control over the pressing process. They are often favored by small businesses or startups that require flexibility and lower initial investment. However, they demand more physical labor and can become bottlenecks as production volume increases.

On the other hand, automatic tablet press machines streamline the production process, offering higher output with consistent quality. These machines are equipped with advanced technology that allows for precision in tablet formation and reduced cycle times, making them ideal for larger-scale operations. They require less operator intervention and can handle significant volumes with minimal oversight.

Assessing your current and future production requirements plays a critical role in determining which type of machine will best suit your needs, ultimately influencing your productivity and cost-effectiveness in the long run.

Cost Considerations: Budgeting for Your Tablets Press Machine Purchase

When it comes to budgeting for a tablet press machine, understanding the cost implications is crucial for any production facility. According to a report by Mordor Intelligence, the global tablet press market is projected to grow at a CAGR of 7.5% from 2021 to 2026, indicating a rising demand for efficient and cost-effective manufacturing solutions. The initial purchase price of tablet press machines can range significantly, typically from $15,000 to over $100,000, depending on their capacity, complexity, and technological features.

In addition to the upfront cost, companies should also consider ongoing expenses such as maintenance, training, and the cost of raw materials. An analysis from Grand View Research suggests that maintenance costs can account for about 15% of the total operating expenses for manufacturing equipment. Furthermore, training staff on the new machine – which can cost anywhere from $1,000 to $5,000 – is essential to ensure efficient production and minimize downtime. Carefully weighing these various cost factors will help manufacturers make informed decisions that align with their production needs and financial realities.

Maintenance and Support: Ensuring Longevity of Your Tablets Press Machine

When investing in a tablet press machine, maintenance and support are crucial factors that significantly influence its longevity and performance. According to the International Society for Pharmaceutical Engineering (ISPE), regular maintenance can enhance machinery lifespan by up to 30%. This includes routine checks of critical components such as hydraulic systems, lubrication levels, and cleanliness of the pressing area. Implementing a structured maintenance schedule not only prevents unexpected downtimes but also maximizes production efficiency and product quality.

Furthermore, choosing a manufacturer that provides comprehensive support can enhance your operational reliability. A 2022 report by the Pharmaceutical Equipment Manufacturers Association (PEMA) indicates that facilities that engage with manufacturers offering robust after-sales service experience a 40% reduction in operational failures. Access to technical support, user training, and readily available spare parts establishes a seamless transition from installation to production, ensuring that your tablet press machine remains in optimal working condition. Investing time in understanding the maintenance needs and support options available will ultimately lead to better production outcomes and increased ROI.

Related Posts

-

How the Best Tablets Press Machine is Shaping the 2025 Industry Tech Landscape

-

A Comprehensive Guide to the Best Tablet Presses for Global Buyers

-

How to Optimize Your Production Efficiency with a Tablet Presser for Maximum Yield

-

How to Optimize Tablet Presser Efficiency with Data Driven Insights on Compression Techniques

-

Mastering Natoli Tablet Press Techniques for Optimal Performance

-

How to Optimize Your Manufacturing Process with a Tablet Presser