Blog

A Comprehensive Guide to the Best Tablet Presses for Global Buyers

In the rapidly evolving pharmaceutical and nutraceutical industries, the demand for high-quality tablet production is at an all-time high. According to a recent market research report by Grand View Research, the global tablet press market is expected to reach USD 1.68 billion by 2025, driven by increasing investments in R&D and the growing popularity of solid dosage forms. Tablet presses, crucial for the efficient manufacturing of tablets, play a significant role in ensuring product consistency and integrity. As global buyers seek reliable solutions, understanding the diverse range of tablet presses available in the market becomes essential. This guide aims to provide a comprehensive overview of the best tablet presses, catering to the unique needs of various industries, while also highlighting key features, technological advancements, and buying considerations.

The Evolving Landscape of Tablet Press Technology: Key Trends for 2025

The tablet press technology landscape is rapidly evolving, with significant trends emerging as we approach 2025. One key trend is the integration of automation in tablet manufacturing processes.

Automated tablet presses are becoming more prevalent, enhancing efficiency, consistency, and reducing human error. These machines not only speed up production but also facilitate real-time monitoring, allowing manufacturers to adjust variables on the fly to maintain optimal quality.

Tip: When considering tablet presses, prioritize machines that offer advanced automation features. This will not only streamline your production process but also ensure a higher standard of quality control.

Another noteworthy trend is the push towards more sustainable practices in tablet production. Manufacturers are increasingly focused on utilizing eco-friendly materials and reducing waste.

Innovations in compression and coating technologies are leading the way to minimize the use of harmful substances and energy consumption, ultimately benefiting both the environment and the bottom line.

Tip: Explore suppliers who emphasize sustainability in their technologies. Investing in eco-friendly solutions can enhance your brand's reputation while meeting the growing demand for environmentally responsible products.

Critical Innovations in Tablet Press Designs: Enhancing Efficiency and Yield

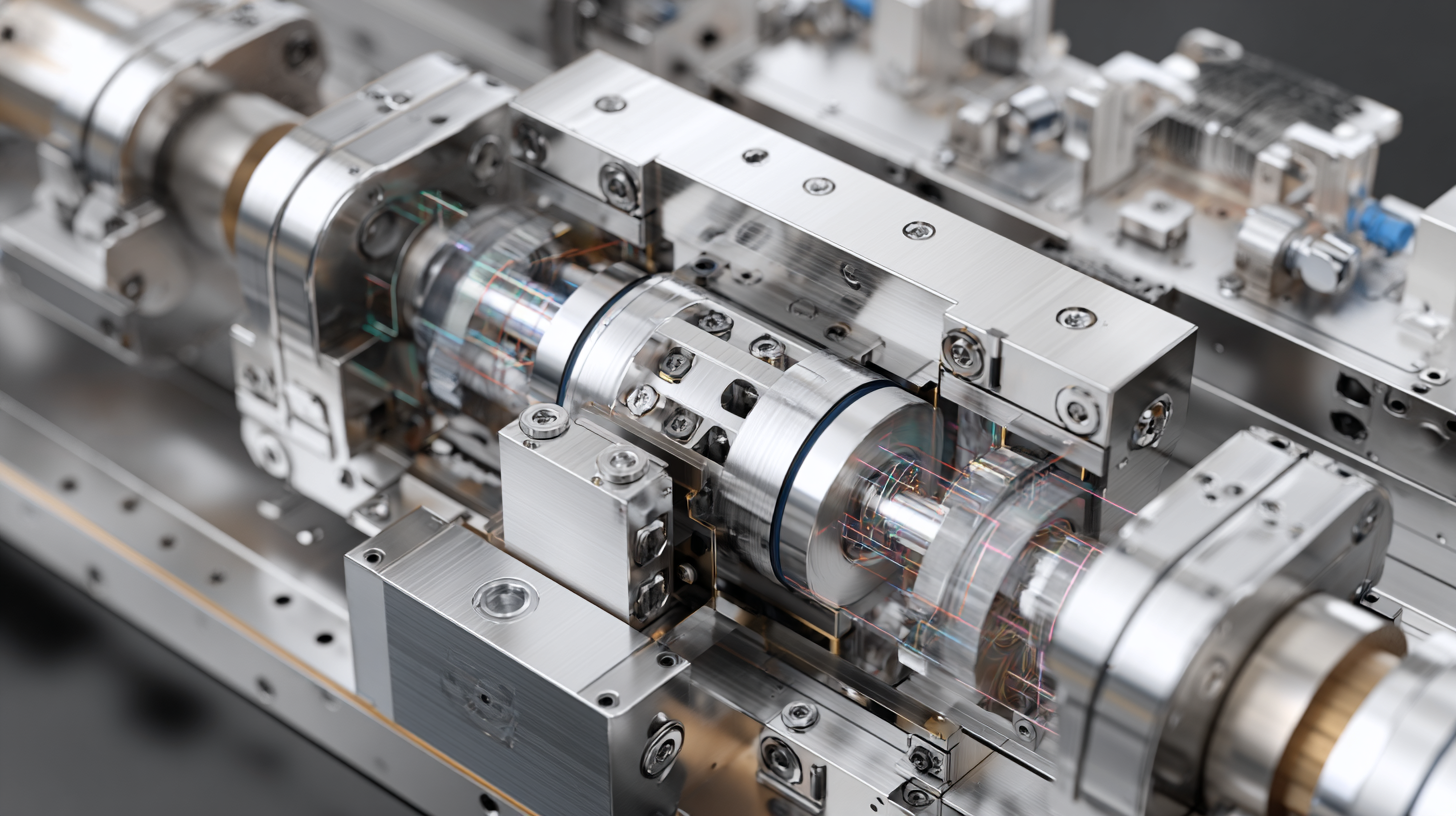

In the rapidly evolving pharmaceutical and nutraceutical industries, the desire for higher efficiency and yield in tablet production has driven critical innovations in tablet press designs. Modern tablet presses are now equipped with advanced technologies such as servo motors and smart sensors. These features enable precise control over the compression process, resulting in reduced tablet weight variation and improved batch consistency. Manufacturers can also monitor production in real-time, allowing for adjustments that enhance productivity without compromising quality.

Additionally, the integration of automation and machine learning in tablet press operations has transformed workflows. Automated cleaning systems ensure minimal downtime, while predictive maintenance capabilities help prevent equipment failures before they occur. These innovations not only streamline the manufacturing process, making it more cost-effective, but they also adhere to stringent regulatory requirements. As global buyers seek relentless quality and efficiency, the latest tablet press designs are essential tools that are set to redefine industry standards and expectations.

The Role of Artificial Intelligence in Tablet Press Operations: A 2025 Perspective

Artificial intelligence is poised to transform tablet press operations significantly by 2025, making them more efficient and reliable. As we adopt advanced technologies within the manufacturing sector, AI's ability to enhance quality control and optimize batch acceptance processes will be crucial. With AI, real-time monitoring can detect deviations in production quality, leading to immediate corrective actions and less waste.

Tips for Implementing AI in Tablet Press Operations:

- Invest in Data Infrastructure: Establish a robust data management system to facilitate seamless integration of AI tools, enabling better analysis and decision-making.

- Train Personnel: Ensure that your workforce is adequately trained to work alongside AI systems, fostering a collaborative environment where technology enhances human capabilities.

- Start Small: Pilot AI solutions on a smaller scale to measure their effectiveness before a full-scale rollout. This approach allows companies to learn and adapt their strategies effectively.

By leveraging AI’s predictive analytics, manufacturers can improve their tablet compression processes and enhance overall operational efficiency. The integration of AI in pharmacy aligns perfectly with the ongoing trend towards Pharma 4.0, which encourages smarter, more data-driven manufacturing processes that ultimately lead to better products and outcomes.

Sustainability in Manufacturing: Eco-Friendly Tablet Press Solutions for Global Buyers

In recent years, the concept of sustainability has transcended mere trend status, evolving into a vital element of consumer consciousness. As buyers become increasingly aware of the environmental impacts of their purchasing decisions, the demand for eco-friendly products has surged. This shift is evident in various sectors, including manufacturing, where tablet presses are now being designed with sustainability in mind. Manufacturers are responding by developing machines that minimize energy consumption, use recyclable materials, and facilitate environmentally responsible production processes.

When selecting a tablet press, consider its energy efficiency and the materials used in its construction. Opt for manufacturers that prioritize sustainable practices, as this not only supports eco-friendly initiatives but also aligns with a growing consumer base that values environmental responsibility. Additionally, look for equipment that enables waste reduction during the production process; this will enhance both your operational efficiency and your brand’s commitment to sustainability.

Investing in sustainability isn’t just about compliance; it’s a strategic move that can enhance your brand reputation and tap into the eco-conscious consumer segment. Engage with suppliers who share your commitment to sustainability and are transparent about their practices. This collaborative approach can lead to innovative solutions that meet market demands while also protecting our planet.

Market Analysis: Strategic Insights on the Best Tablet Press Brands for Global Buyers in 2025

As the tablet manufacturing industry evolves, understanding the market dynamics is crucial for global buyers seeking the best tablet presses. The landscape is shaped by rapid technological advancements, evolving consumer preferences, and stringent regulatory requirements. In 2025, key players like Bosch, Fette Compacting, and KORSCH are expected to dominate the market, offering innovative solutions that enhance efficiency and product quality. Their commitment to R&D ensures that buyers will have access to cutting-edge features such as advanced automation, real-time monitoring, and improved compression techniques that cater to diverse production needs.

Additionally, sustainability and energy efficiency are becoming focal points for buyers when choosing tablet presses. Brands that prioritize eco-friendly practices and materials are likely to gain a competitive edge. Market analysis reveals a growing demand for presses that optimize resource usage while maintaining high throughput, thus driving manufacturers to innovate. Understanding these strategic insights will empower global buyers in making informed decisions that align with their operational goals, ultimately ensuring they invest in tablet presses that offer the best return on investment and adaptability to future trends.

A Comprehensive Guide to the Best Tablet Presses for Global Buyers - Market Analysis: Strategic Insights on the Best Tablet Press Brands for Global Buyers in 2025

| Type of Tablet Press | Max Output (tablets/hour) | Die Size (mm) | Weight (kg) | Price Range (USD) |

|---|---|---|---|---|

| Single Punch Tablet Press | 8,000 | 12 | 500 | 5,000 - 10,000 |

| Rotary Tablet Press | 30,000 | 25 | 700 | 15,000 - 25,000 |

| Double-Sided Tablet Press | 50,000 | 18 | 1000 | 30,000 - 50,000 |

| Hydraulic Tablet Press | 2,000 | 10 | 300 | 3,000 - 7,000 |