Blog

How to Maximize Efficiency in Your Powder Pulverizer Operations for Optimal Product Output

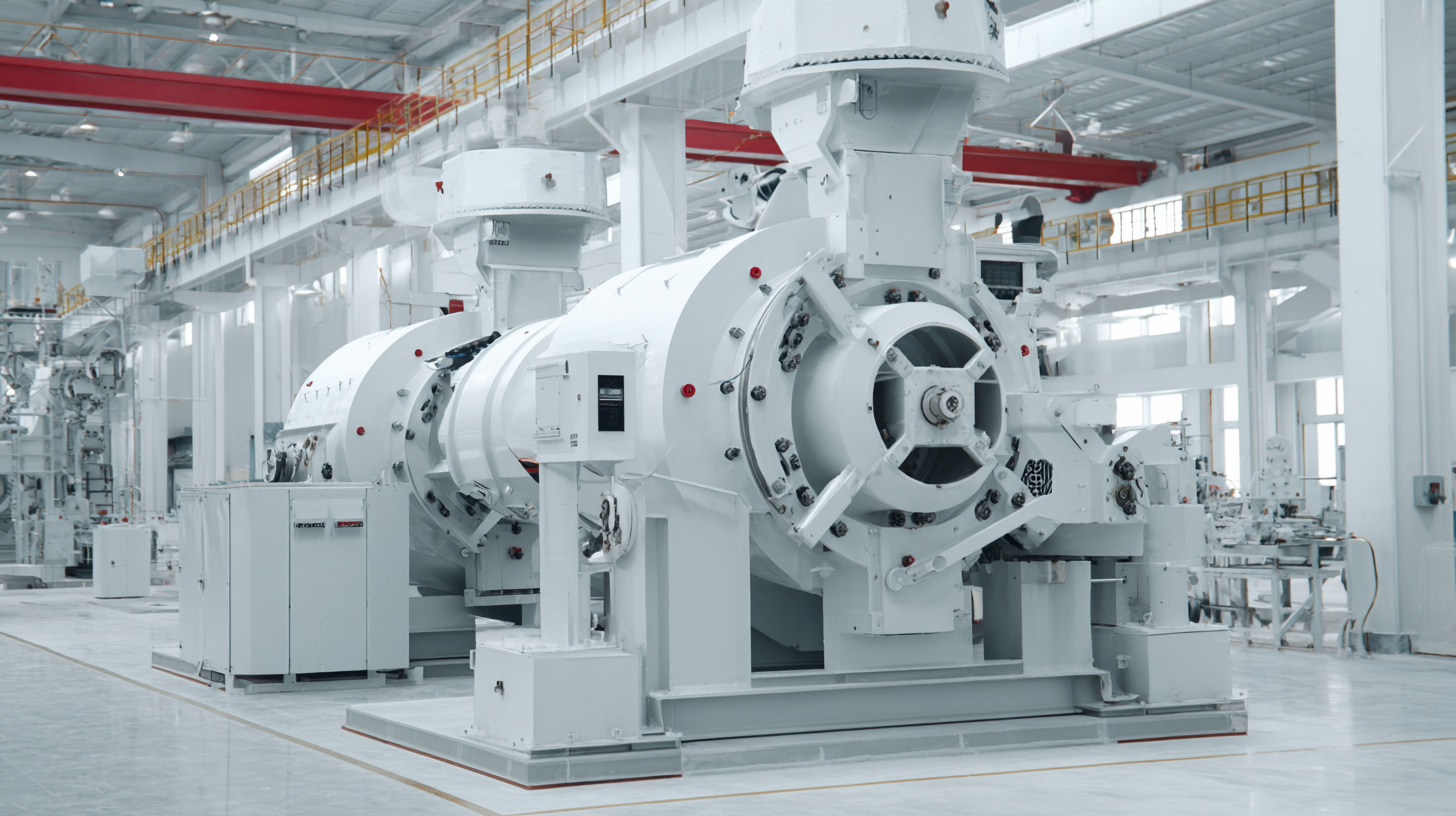

In the competitive landscape of powder processing, optimizing the efficiency of your Powder Pulverizer operations is crucial for achieving superior product output. As industries increasingly demand finer, more uniform particle sizes, the role of the Powder Pulverizer becomes even more critical. Enhancing the operational effectiveness of these machines not only increases throughput but also improves product quality, leading to higher customer satisfaction and profitability.

This guide will explore essential strategies—blending innovative technologies with best practices—to maximize the efficiency of your Powder Pulverizer. By focusing on these key areas, operators can streamline processes, reduce downtime, and ensure that their Pulverizer is performing at its best, ultimately setting the stage for optimal production efficiency and a competitive edge in the market.

Understanding the Basics of Powder Pulverizer Operations for Maximum Efficiency

Understanding the basics of powder pulverizer operations is crucial for maximizing efficiency and achieving optimal product output. The pulverization process involves the breakdown of raw materials into fine powders, and factors such as feed rate, grinding speed, and machine maintenance significantly affect performance. A well-timed feed rate ensures that the materials are processed efficiently without causing clogging or excessive wear on the machinery. By monitoring these variables, operators can fine-tune their equipment settings, ensuring the pulverizer operates at peak efficiency.

Moreover, maintaining the pulverizer in good condition is essential for consistent output quality. Regular inspections and timely replacement of worn-out parts prevent unexpected downtime and keep the machinery running smoothly. Understanding the types of materials being processed and their respective properties also plays a vital role in optimizing the pulverization process. For instance, adjusting the grinding mechanism based on the hardness or moisture content of the material can considerably enhance productivity. By focusing on these foundational aspects, operators can significantly boost their powder pulverizer operations, leading to increased efficiency and output quality.

Key Factors Affecting Pulverizer Performance and Product Output

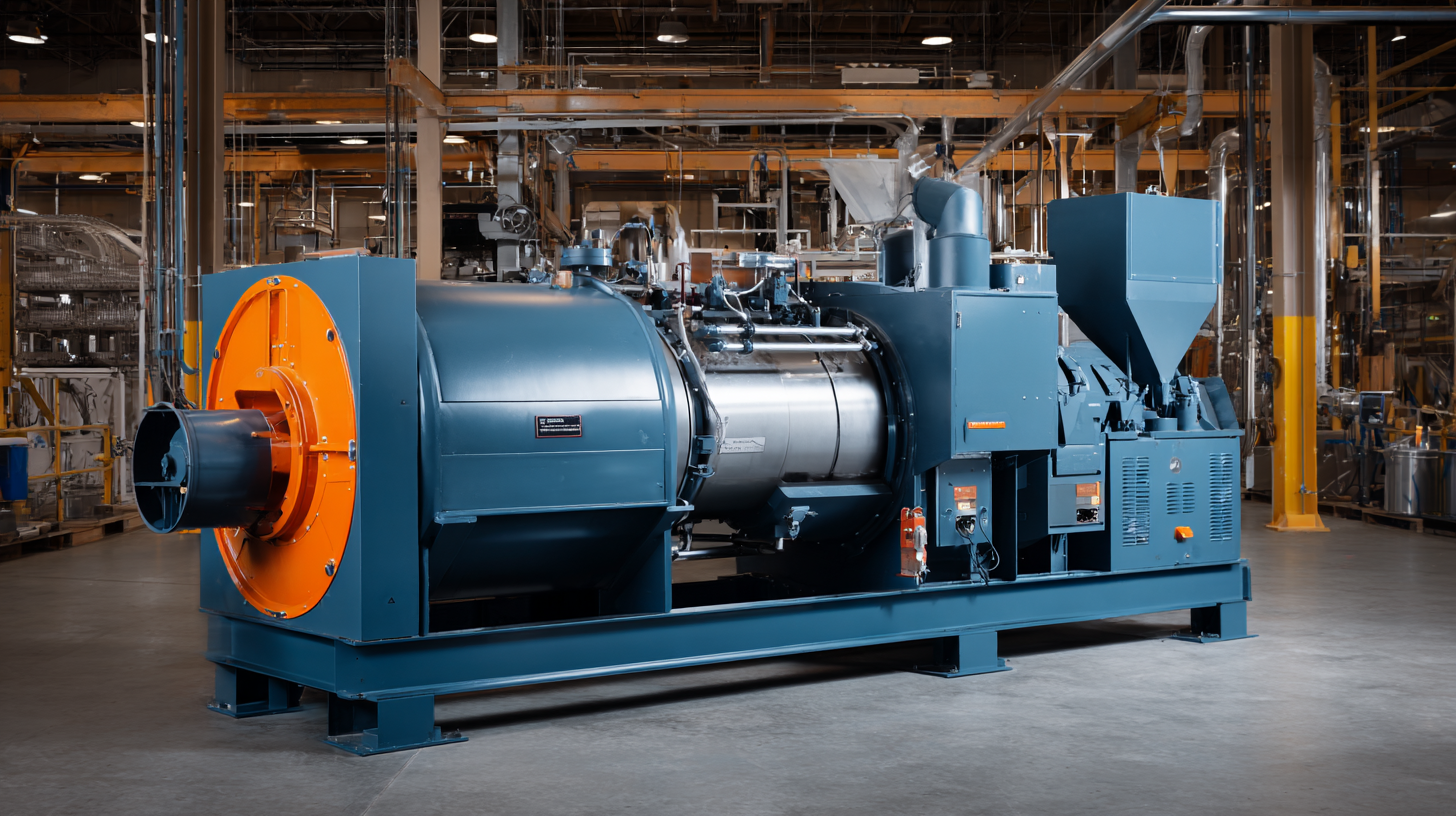

In optimizing powder pulverizer operations, understanding the key factors that affect performance and product output is essential. Equipment choice plays a crucial role; for instance, advancements in mobile crushing and screening technologies have significantly increased production capabilities within the aggregate sector. The latest innovations ensure that pulverizers can operate at higher efficiencies, allowing for greater throughput while maintaining product quality. Additionally, regular maintenance of the pulverizing equipment is vital for sustaining high performance, as operational reliability contributes directly to output levels.

Moreover, environmental conditions and material characteristics are also pivotal in pulverizer effectiveness. For example, heat build-up during processing can degrade product quality, particularly in sensitive materials like spices. Employing advanced grinding techniques can mitigate these effects, ensuring that optimal particle size distribution is achieved without compromising material integrity. By focusing on these factors, operators can enhance their pulverizing processes, leading to higher quality products and increased output efficiency.

Best Practices for Routine Maintenance in Pulverizer Equipment

Routine maintenance is crucial for ensuring the optimal performance of your powder pulverizer. Regular inspection of the equipment can help identify potential issues before they escalate, thereby reducing downtime and improving productivity. Ensuring that all components, including blades and screens, are clean and free from debris will enhance the efficiency of the pulverization process.

Tips for Maintenance:

- Schedule regular maintenance checks to examine wear and tear on critical parts. This will help maintain consistency in product quality and prevent unexpected breakdowns.

- Lubricate moving parts as recommended by the manufacturer. Proper lubrication significantly reduces friction, prolonging the lifespan of the pulverizer.

- Regularly replace or sharpen blades to ensure they function effectively, which is vital for achieving the desired particle size and minimizing energy consumption.

Implementing these best practices into your routine can greatly improve the overall reliability and efficiency of your powder pulverizer operations. Keeping detailed logs of maintenance activities can also help in troubleshooting and maintaining optimal output.

Optimizing Process Parameters for Enhanced Efficiency in Powder Processing

Optimizing process parameters in powder pulverization is crucial for enhancing overall efficiency and ensuring optimal product output. According to a recent report by Industry Research, the global powder processing market is projected to reach $4 billion by 2026, driven largely by advancements in technology that allow for more precise control of pulverizer operations. Key parameters such as feed rate, particle size reduction, and operational temperature significantly influence the performance of these systems. By meticulously adjusting these factors, manufacturers can reduce energy consumption and waste, leading to increased throughput and improved product quality.

One effective strategy is to utilize real-time monitoring systems to fine-tune process parameters continuously. A study from the American Chemical Society found that real-time analytics could improve production efficiency by up to 20%. By incorporating data-driven insights, operators can identify optimal settings for their equipment, ensuring that the pulverization process is not only efficient but also consistent in producing uniform particle sizes. Furthermore, investing in high-efficiency pulverizers equipped with advanced technology can significantly enhance operational output, reducing costs while meeting the rising demand for high-quality powdered materials across various industries.

Maximizing Efficiency in Powder Pulverizer Operations

This bar chart illustrates the key performance metrics for maximizing efficiency in powder pulverizer operations. The metrics include Feed Rate, Energy Consumption, Output Size, and Operational Time, critical for optimizing process parameters in powder processing.

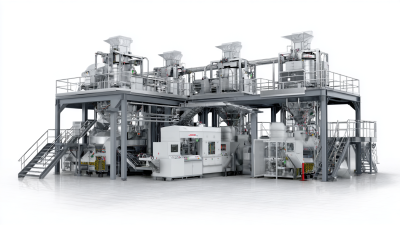

Advanced Technologies and Innovations in Powder Pulverization Techniques

In the realm of powder pulverization, the integration of advanced technologies is transforming operational efficiencies significantly. Innovations such as ultrafine grinding techniques and advanced air classifier systems have been pivotal. According to a report by MarketsandMarkets, the global powder processing market is expected to grow from $7.3 billion in 2021 to $11.5 billion by 2026, highlighting a compound annual growth rate (CAGR) of 9.4%. This surge is indicative of the increasing demand for more efficient processes that yield higher product output with reduced energy consumption.

Moreover, the implementation of smart technology and IoT-enabled machines in pulverizer operations enhances monitoring and control. Real-time data analytics provides insights into operational performance, allowing for predictive maintenance and reduced downtime. A study published by TechNavio illustrates that companies adopting these technologies can improve their output quality by 15% while decreasing operational costs by up to 30%. These advancements not only optimize production but also contribute to a more sustainable manufacturing environment, as they minimize waste and energy usage, aligning with industry goals for green manufacturing practices.

Related Posts

-

How the Best Powder Pulverizer Transforms Food Processing: Industry Case Studies and Insights

-

Ultimate Guide to Choosing the Best Powder Pulverizer for Your Industrial Needs

-

How to Master the Art of Powder Pulverization for Optimal Results

-

Exploring Unique Options for Mesin Mixer Powder in Industrial Applications

-

What Is a Powder Mixture Machine and How Does It Revolutionize Material Processing?

-

How to Optimize Your Oral Thin Film Pouching Process for Better Results