Blog

Top Tips for Choosing the Right Mixing Powder Machine?

Choosing the right Mixing Powder Machine is essential for any business. It can directly impact your production quality. With many options available, making the right choice can be challenging.

When selecting a Mixing Powder Machine, consider the materials you will use. Different machines handle various powders differently. Some powders require gentle mixing, while others need intense blending. It's important to match the machine to your specific needs.

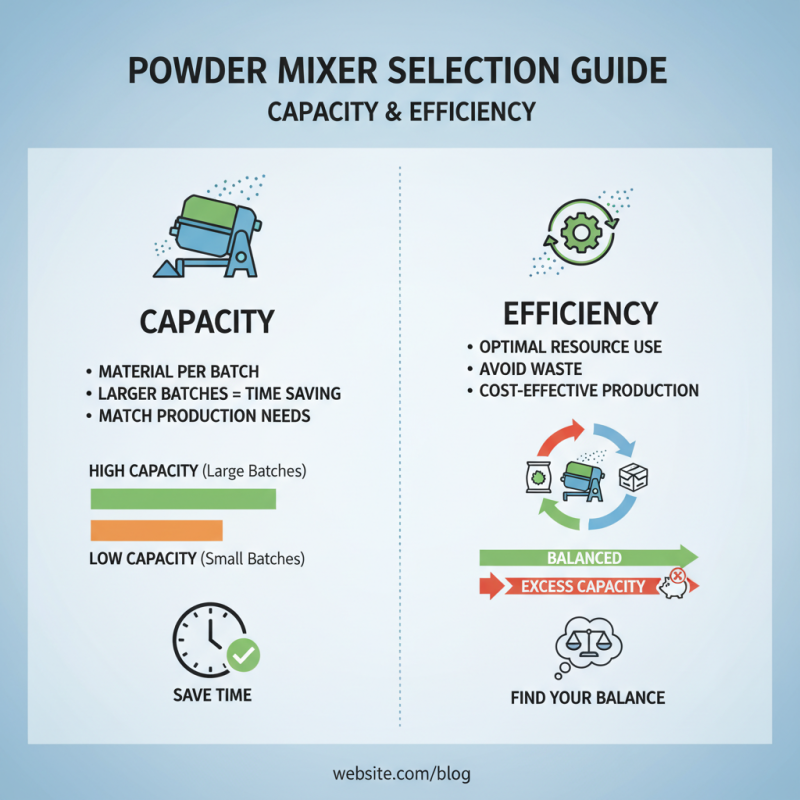

Another aspect to reflect on is the machine's capacity. A machine too small will slow down your process. Conversely, a larger machine may seem wasteful if not fully utilized. Understand your production demands carefully. Finding a balance is key to maximizing efficiency and minimizing waste.

Understanding the Importance of Mixing Powder Machines in Production

Mixing powder machines play a crucial role in various industries, from pharmaceuticals to food processing. According to a report by MarketsandMarkets, the global market for mixing equipment is projected to reach $6.2 billion by 2025, fueled by advancements in technology. Efficient blending ensures uniformity and quality, directly impacting product performance and consistency. Inconsistent mixtures can lead to subpar products, affecting brand reputation and customer satisfaction.

Selection of the right mixing machine is vital. Understanding material properties is key. Different powders have varying behaviors during the mixing process. For instance, some may clump, while others can be highly fluid. A misstep in machine choice can result in ineffective mixing and wasted resources, leading to costly production delays. An industry study revealed that nearly 30% of manufacturers faced complaints due to poor mixing practices.

Moreover, maintenance of mixing equipment is often overlooked. Neglecting regular checks can lead to operational hiccups and reduced lifespan. Innovations like automated monitoring systems are emerging. These can help detect issues early. However, they require investment and a shift in operational mindset. Being aware of these factors offers a glimpse into the complexities behind what seems like a straightforward process.

Key Features to Consider When Selecting a Mixing Powder Machine

When selecting a mixing powder machine, key features can significantly impact performance. One crucial aspect is the machine’s capacity. Industry reports show that machines with a capacity range from 50 to 500 liters are commonly preferred. They offer versatility for various production scales. However, smaller operations may struggle with overcapacity, leading to inefficiency and increased costs.

Another important feature is the mixing technology used. Machines may employ paddle, ribbon, or V-type mixing methods. For instance, a study indicates that ribbon mixers can reduce mixing time by 30% compared to traditional methods. Yet, this efficiency can sometimes lead to uneven mixtures if not monitored closely. Thoroughly understanding the material characteristics can help mitigate this issue.

Ease of cleaning is also vital. According to industry standards, a machine should minimize the risk of cross-contamination. Some designs are inherently more difficult to clean. Consequently, operators may overlook this feature, compromising hygiene. Balancing these essential factors requires careful consideration to enhance operational effectiveness while avoiding potential pitfalls.

Top Tips for Choosing the Right Mixing Powder Machine

The following bar chart presents key features to consider when selecting a mixing powder machine, along with their importance ratings based on industry feedback.

Different Types of Mixing Powder Machines and Their Applications

When selecting a mixing powder machine, understanding the different types available is crucial. Each machine serves specific purposes based on the material being processed. For instance, the ribbon blender is popular for its efficiency in mixing bulk powders. It utilizes a double helix ribbon to ensure uniform distribution of ingredients. Perfect for food and chemical industries, it's great for dry blending.

However, the question arises: is it always the right choice? Not necessarily. Another type, the plow mixer, offers better results for heavier materials. It features plow-shaped blades that lift and fold the powders. Often used in plastic and metal powder processing, it excels where density is a concern. Users sometimes overlook this option.

Understanding the application of each machine is vital for success. Some mixers work better for smaller batches, while others handle larger volumes. Choosing incorrectly can lead to inefficient mixing or even product waste. Reflecting on specific requirements can guide the decision. Working with a knowledgeable supplier can also help refine choices and avoid pitfalls.

Evaluating the Capacity and Efficiency of Mixing Powder Machines

When choosing a mixing powder machine, understanding its capacity and efficiency is crucial. Capacity refers to how much material the machine can handle at one time. A higher capacity allows for larger batches and can significantly save time. However, a machine with excessive capacity may lead to wasted resources if your production needs are lower. Balancing these aspects is essential.

Efficiency often determines the quality of the mix. A machine that blends quickly and evenly can enhance product consistency. However, faster does not always mean better. Sometimes, mixing too quickly can lead to inaccuracies in the blend. Observing the mixing time and ensuring uniformity is vital. Additionally, consider the machine’s design. Convoluted structures might complicate the mixing process. Simple designs tend to be easier to clean and maintain.

In evaluating your options, reflect on your specific requirements. Think about your production volume, product characteristics, and desired outcomes. Each machine has its strengths and weaknesses. Not all machines are suited for every material. Take your time to analyze your choices carefully. This will ultimately lead to better decisions and more efficient operations.

Assessing Maintenance Needs and Costs for Mixing Powder Machines

When selecting a mixing powder machine, assessing maintenance needs is vital. Regular maintenance ensures efficiency and longevity. Consider costs when budgeting for your equipment. It's essential to track wear and tear over time. This helps in anticipating future expenses.

Tips to think about: check how often you will need servicing. Some machines require more frequent upkeep. Also, review user manuals for specific maintenance schedules. This ensures you won't overlook essential tasks. Pay attention to the noise level too; high noise may indicate mechanical issues.

Look into warranty options as well. A good warranty reduces potential costs. However, investigate what's covered. Not all warranties offer comprehensive protection. Reflect on your choices and the importance of reliable service. A small oversight can lead to bigger problems later.

Related Posts

-

2026 Top Mixing Powder Machine Features and Benefits?

-

Revolutionizing Infant Nutrition: The Science Behind the Powder Milk Mixer

-

Ultimate Guide to Selecting the Best Powder Mixture Machine for Your Needs

-

Why You Need a Mixing Powder Machine for Your Manufacturing Success

-

Ultimate Guide to Choosing the Best Powder Mixers for Your Business Needs

-

Understanding the Efficiency of Powder Mixers in Modern Manufacturing