Blog

Top Capsule Filling Equipment for Efficient Pharmaceutical Production?

In the fast-evolving world of pharmaceuticals, efficiency is key. As the demand for high-quality medications rises, the importance of advanced Capsule Filling Equipment cannot be overstated. Dr. Emily Carter, a leading expert in pharmaceutical manufacturing, states, "The right filling equipment can streamline production and enhance product quality." This highlights the need for reliable machinery in today’s production lines.

Capsule Filling Equipment has become essential for pharmaceutical companies aiming for efficiency. Innovations in this field allow for faster filling, fewer errors, and better consistency. Companies are investing in technologies that provide precision in dosages and minimize waste. However, selecting the right equipment poses challenges. Not all machines fit every production line, and some may require significant adjustments.

While advancements are impressive, there is always room for improvement. For example, some equipment may be too complex to operate efficiently. Additionally, training staff to use these machines effectively can take time and resources. The balance between speed and accuracy must be carefully managed. With the right approach, Capsule Filling Equipment can transform production efficiency and product reliability.

Types of Capsule Filling Equipment in Pharmaceutical Production

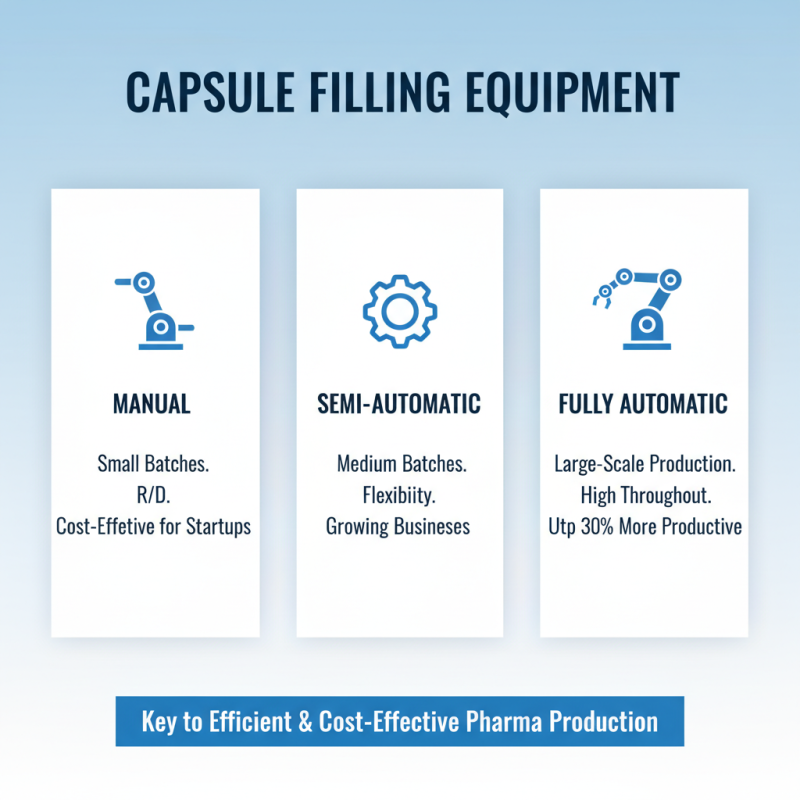

Capsule filling equipment plays a crucial role in pharmaceutical production. Various types ensure that the process is efficient and cost-effective. Manual, semi-automatic, and fully automatic machines are common in the industry. Each type serves a specific purpose, catering to different production scales. Manual machines suit small batches while automatic models fit large-scale operations. A recent industry report suggests that automated systems can increase productivity by up to 30%.

Semi-automatic machines offer a balance between speed and control. They allow operators to oversee the filling process while improving cycle times. However, relying solely on automation has its flaws. Human oversight is still essential to maintain quality control. An ineffective setup might lead to inconsistent fills. Statistics show that nearly 15% of products face rejection due to filling errors. This highlights the importance of proper machinery selection and maintenance.

Moreover, capsule filling technology is continuously evolving. Recent advancements include improved dosing systems and enhanced cleaning processes. These innovations reduce downtime and enhance overall efficiency. However, technology alone cannot guarantee success. Operators must understand their equipment deeply. Inadequate training could hamper the advantages provided by cutting-edge machines. As the industry grows, so does the complexity of capsule filling equipment, requiring continuous adaptation.

Key Features of Efficient Capsule Fillers for Pharmaceuticals

In the pharmaceutical industry, efficient capsule filling is crucial for production. Advanced capsule fillers significantly boost productivity and product quality. Key features of these machines greatly enhance their effectiveness.

Automation is vital. Modern capsule fillers often incorporate automated processes that reduce human error. According to industry studies, automation can increase output by up to 40%. Precision is also crucial. High-quality fillers ensure accurate dosages, leading to fewer errors. A study showed that precise filling can lower reject rates by 15%.

Tips: Always choose equipment that offers quick changeovers. This feature reduces downtime between production batches.

Flexibility in production is another important aspect. The best machines can handle different capsule sizes and formulations. This adaptability is essential in today’s dynamic market. Yet, not all machines can efficiently switch between various products, which can lead to operational delays.

Investing in robust training for operators is critical. Skilled personnel can maximize the potential of filling machines. This step often gets overlooked but is essential for maintaining efficiency.

Top Capsule Filling Equipment for Efficient Pharmaceutical Production

| Model | Production Capacity (Capsules/hour) | Filling Accuracy (%) | Power Consumption (kW) | Dimensions (L x W x H, mm) | Key Features |

|---|---|---|---|---|---|

| Model A | 20,000 | 99.5 | 5.5 | 1500 x 800 x 1800 | Automatic operation, Easy maintenance |

| Model B | 25,000 | 99.8 | 6.0 | 1600 x 900 x 1900 | High-speed filling, User-friendly interface |

| Model C | 15,000 | 99.2 | 4.5 | 1400 x 700 x 1700 | Compact design, Cost-effective |

| Model D | 30,000 | 99.9 | 7.0 | 1700 x 1000 x 2000 | Advanced automation, High reliability |

Benefits of Automated Capsule Filling Systems in Manufacturing

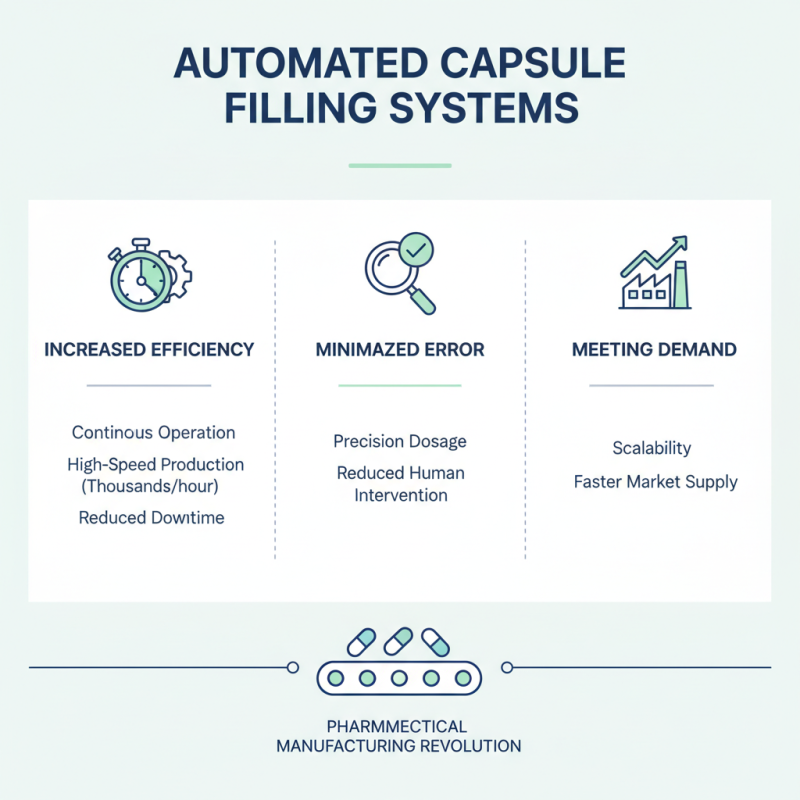

Automated capsule filling systems revolutionize pharmaceutical manufacturing. They enhance efficiency and minimize human error. These systems can operate continuously, reducing downtime significantly. High-speed machines can fill thousands of capsules per hour. This is essential for meeting growing market demands.

Tips: Choose a system that suits your production scale. A machine that is too advanced may not match your current needs. Conversely, an underperforming system could waste resources. Consider compatibility with your existing processes.

Automation also allows for better quality control. Monitoring systems ensure accurate dosing and proper sealing. This reduces the risk of contamination. However, relying entirely on automation may neglect operator training. It's vital to strike a balance between technology and skilled personnel. This leads to a more robust production process.

Investing in automated systems can be costly, but consider long-term benefits. Examine your production goals. Focus on areas where automation can drive efficiency. Implement gradual changes to avoid overwhelming the workforce. This approach helps in building a more resilient manufacturing environment.

Factors Influencing the Choice of Capsule Filling Equipment

When selecting capsule filling equipment, several factors come into play. One key aspect is production capacity. A report by MarketsandMarkets indicates that the global capsule filling equipment market is expected to reach $1.3 billion by 2024, reflecting strong demand. Companies must consider throughput. Higher output is essential for meeting increasing pharmaceutical demands.

Another crucial factor is the equipment’s adaptability. Flexibility in capsule types and sizes can significantly affect production efficiency. According to a study by Grand View Research, clients prefer machines that can accommodate various formulations. This allows for quicker adjustments to changing market needs. However, these versatile machines often come with a steep learning curve, which can slow down initial operations.

Cost is also a determining element but may lead to a trade-off. The cheapest option may not always offer the best reliability or efficiency. The right equipment can enhance quality and reduce overall costs in the long run. Yet, many manufacturers still overlook the importance of investing in robust, durable machinery. This can lead to increased maintenance costs and production downtime. Companies should reflect on these trade-offs to avoid costly mistakes in their selection process.

Maintenance and Best Practices for Capsule Filling Machines

Maintaining capsule filling machines is crucial for operational efficiency. Regular checks can prevent costly downtimes. According to industry reports, well-maintained equipment can improve productivity by up to 30%. Delaying maintenance often leads to larger issues. This impacts both output and quality.

Cleaning is a key part of maintenance. Residue buildup can affect filling accuracy. Regularly scheduled cleaning routines are essential. They can help sustain machine performance. Experts recommend a cleaning protocol after every production cycle. This minimizes contamination risks.

Trained personnel should perform maintenance tasks. Their familiarity with equipment intricacies can enhance performance. However, not all facilities invest in appropriate training. This oversight can lead to errors in machine operation. Data shows that effective training reduces equipment failures by 25%. With proper practices, facilities can achieve higher efficiency and product reliability. Investing in both machine upkeep and staff training pays off.

Top Capsule Filling Equipment Performance in Pharmaceutical Production

Related Posts

-

Step-by-Step Guide to Mastering Capsule Filling Equipment: Tips and Techniques

-

What is Capsule Filling Equipment and Its Impact on Pharmaceutical Production Efficiency?

-

Unlocking Efficiency: How Capsule Filling Equipment Revolutionizes the Supplement Industry

-

How to Choose the Right Capsule Filling Equipment for Your Business Needs

-

Revolutionizing Your Production Line: The Ultimate Guide to Capsules Filling Machines

-

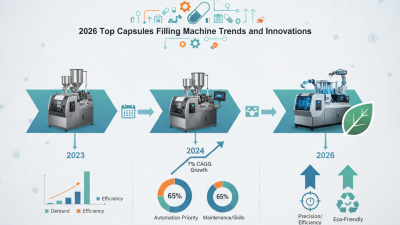

2026 Top Capsules Filling Machine Trends and Innovations?