Blog

2026 Top Mixing Powder Machine Features and Benefits?

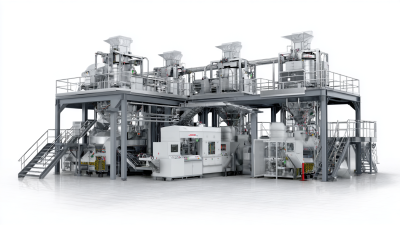

In the ever-evolving landscape of industrial automation, the role of the Mixing Powder Machine has become increasingly vital. As of 2023, the global demand for mixing equipment in various sectors is projected to grow significantly. According to a report, the market for mixing technologies is expected to reach $8 billion by 2025. This trend indicates a robust need for efficient, high-quality blending solutions.

Mixing Powder Machines are known for their versatility and efficiency. They facilitate uniform distribution of powders, which is crucial in industries like pharmaceuticals, food processing, and materials manufacturing. However, not all machines offer optimal performance. Some models struggle with specific powder types, leading to inconsistent mixtures. Such shortcomings highlight the importance of choosing the right equipment that aligns with industry standards.

The features and benefits of a Mixing Powder Machine are often touted, yet many users overlook potential limitations. The balance between performance and maintenance is critical. Identifying machines with easy-to-use interfaces can enhance workflow. Furthermore, considering energy consumption is essential for sustainability. As the industry progresses, ongoing evaluation and innovation in mixing technologies will shape future developments.

Key Features of 2026 Top Mixing Powder Machines

When considering the key features of top mixing powder machines in 2026, efficiency stands out. Advanced machines boast mixing speeds of over 300 RPM. This translates into faster production times, ideal for high-demand industries. Studies show that businesses using this technology report a 20% increase in output. However, speed isn't everything. Precision in mixing is critical.

Another important feature is automation. Modern machines come equipped with automatic controls. These systems minimize human error and enhance consistency. A recent industry report cited that automated processes can reduce labor costs by approximately 15%. Yet, it raises concerns about dependence on technology. Over-reliance can lead to challenges if systems fail. Additionally, maintenance is a critical aspect. Neglecting regular checks can cause downtime.

Moreover, versatility is essential. Machines should handle different powders effortlessly. Flexibility in production lines is increasingly vital. Data indicates that 40% of manufacturers are focusing on adaptable machinery this year. However, balancing versatility with performance remains complex. Some machines sacrifice mixing quality for adaptability. These trade-offs must be carefully evaluated.

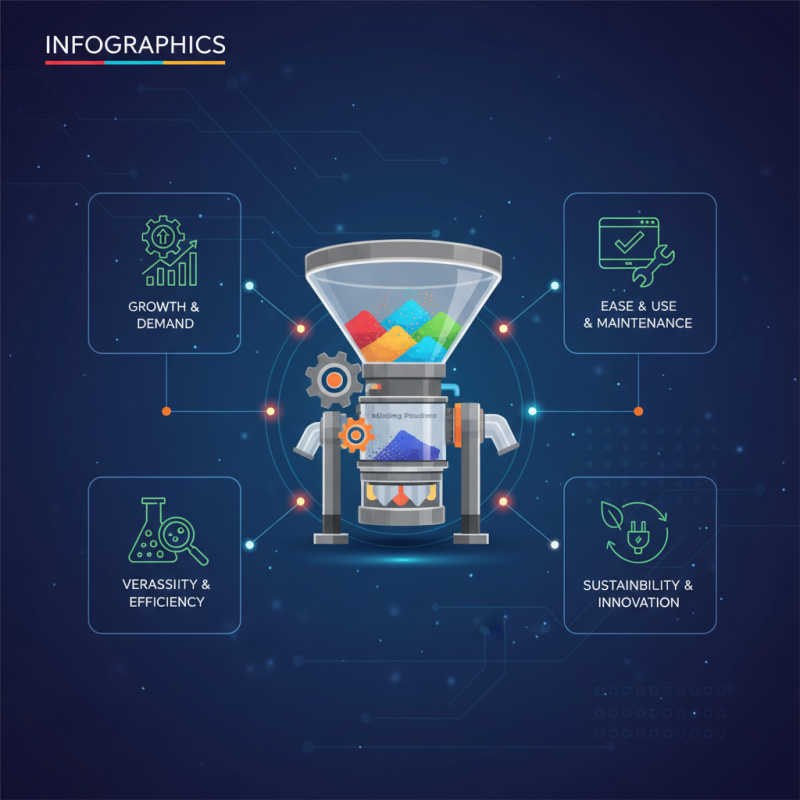

2026 Top Mixing Powder Machine Features and Benefits

This chart illustrates the key features of top mixing powder machines in 2026, showcasing their performance in various aspects such as mixing efficiency, energy consumption, user-friendliness, and maintenance requirements.

Benefits of Advanced Mixing Technology in 2026

In 2026, the evolution of mixing technology brings substantial benefits. Advanced mixing machines are now efficient and precise. They ensure uniformity in product quality, crucial for industries like food processing and pharmaceuticals. The ability to mix at varying speeds enhances control over the final product.

Tip: Regular maintenance can extend the lifespan of mixing machines.

Operators appreciate user-friendly interfaces. These interfaces simplify the monitoring of mixing parameters. Intuitive controls reduce the likelihood of errors during operations, which can be costly. However, some users may struggle to adapt to new technologies, causing temporary setbacks.

Tip: Provide training sessions for staff on new equipment.

The integration of smart technology is a game changer. Real-time data tracking allows for quick adjustments. While this may improve performance, not all machines are compatible with existing systems. This presents challenges, often requiring additional investments and time for integration.

Types of Mixing Mechanisms Used in Modern Powder Machines

Modern powder mixing machines incorporate various mixing mechanisms to achieve desired outcomes. One common system is the ribbon blender. This design features dual helical ribbons that ensure materials blend uniformly. The design minimizes dead spots, but it may not handle very viscous powders well.

Another mechanism is the paddle mixer. With its broad paddles, it allows for gentle mixing. This is great for delicate materials but has its limitations. For instance, achieving a fine blend can take longer than with other methods.

Tumble mixers are also popular. They use gravity to mix powders. While they are effective for bulk materials, they sometimes struggle with achieving consistent homogeneity. Each mixing mechanism has advantages and challenges. Understanding these can help industries make informed choices.

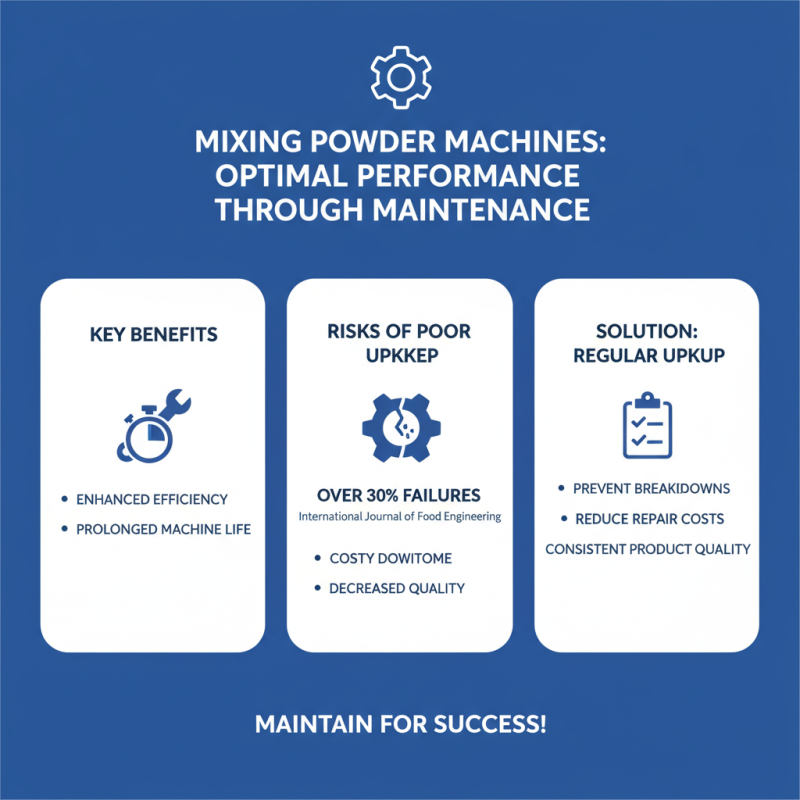

Best Practices for Maintaining Mixing Powder Machines

Maintaining mixing powder machines is crucial for optimal performance. Regular upkeep can enhance efficiency and prolong machine life. A study from the International Journal of Food Engineering shows that over 30% of equipment failures are linked to inadequate maintenance. These failures often lead to costly downtimes and decrease product quality.

Routine checks should include inspecting seals, belts, and overall cleanliness. Dust particles can accumulate, affecting the mixing process. Neglecting this step can lead to uneven blending and product inconsistency. Additionally, lubricating moving parts reduces wear and tear. Data indicates that proper lubrication can improve machine lifespan by up to 25%.

Operators should also be trained to recognize early signs of malfunction. Insufficient training often results in overlooked issues. When operators understand the machinery better, they can prevent minor problems from escalating. Regular training sessions can lead to a noticeable drop in maintenance-related issues. Create a checklist for daily inspections to ensure nothing gets missed. Inadequate attention now can lead to bigger problems later.

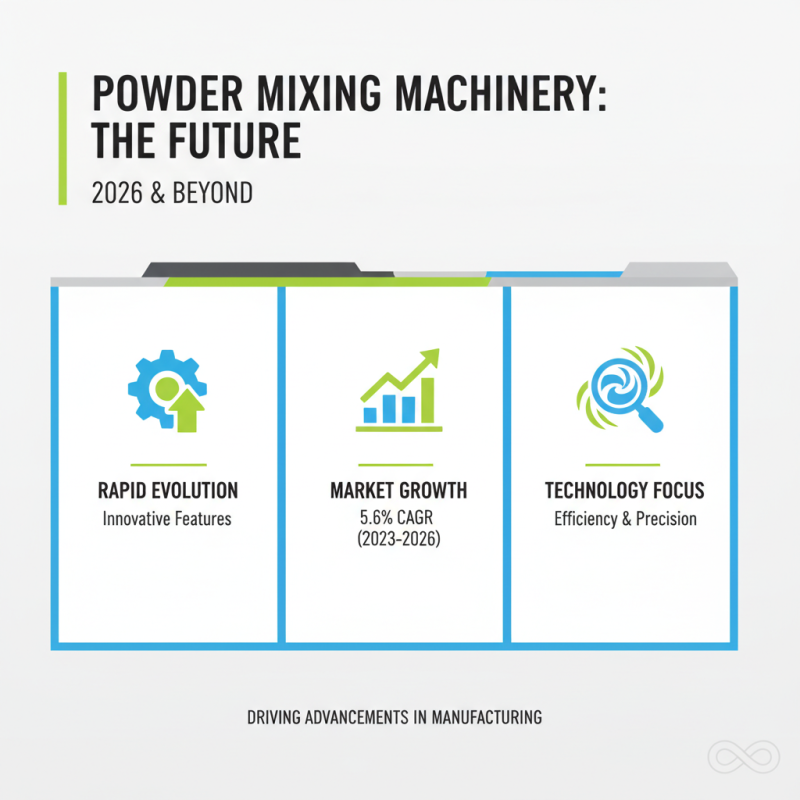

Future Trends in Powder Mixing Machinery for 2026 and Beyond

The future of powder mixing machinery is evolving rapidly, with innovative features expected to dominate in 2026 and beyond. Industry reports indicate that the global powder mixing market is projected to grow at a CAGR of 5.6% from 2023 to 2026. This growth will drive advancements in mixing technology, emphasizing efficiency and precision.

One trend is the integration of smart technology. Machines equipped with IoT capabilities can monitor mixing parameters in real-time. This data can help operators adjust processes dynamically, ensuring consistent product quality. A study by the Machinery Innovation Centre highlighted that smart mixing systems could reduce product variability by up to 30%. However, not all operators are ready for this technological shift. Concerns about data security and the need for training persist.

Another emerging trend is the focus on sustainability. As regulations tighten, manufacturers are turning to eco-friendly materials and practices. Research indicates that machines designed for energy efficiency can cut operational costs by 15%. Despite this, many companies struggle with the initial investment in sustainable technology. The transition is not always seamless, as older equipment may need significant upgrades or replacements. These challenges must be addressed for the industry to fully embrace the future of powder mixing.

Related Posts

-

Revolutionizing Infant Nutrition: The Science Behind the Powder Milk Mixer

-

Why You Need a Mixing Powder Machine for Your Manufacturing Success

-

Top 10 Benefits of Using a Powder Mixture Machine in Manufacturing

-

Why Investing in a Mesin Mixer Powder is Essential for Your Production Efficiency

-

What Is a Powder Mixture Machine and How Does It Revolutionize Material Processing?

-

Ultimate Guide to Selecting the Best Powder Mixture Machine for Your Needs