Blog

5 Unmatched Mixer Powder Applications Transforming Your Production Process

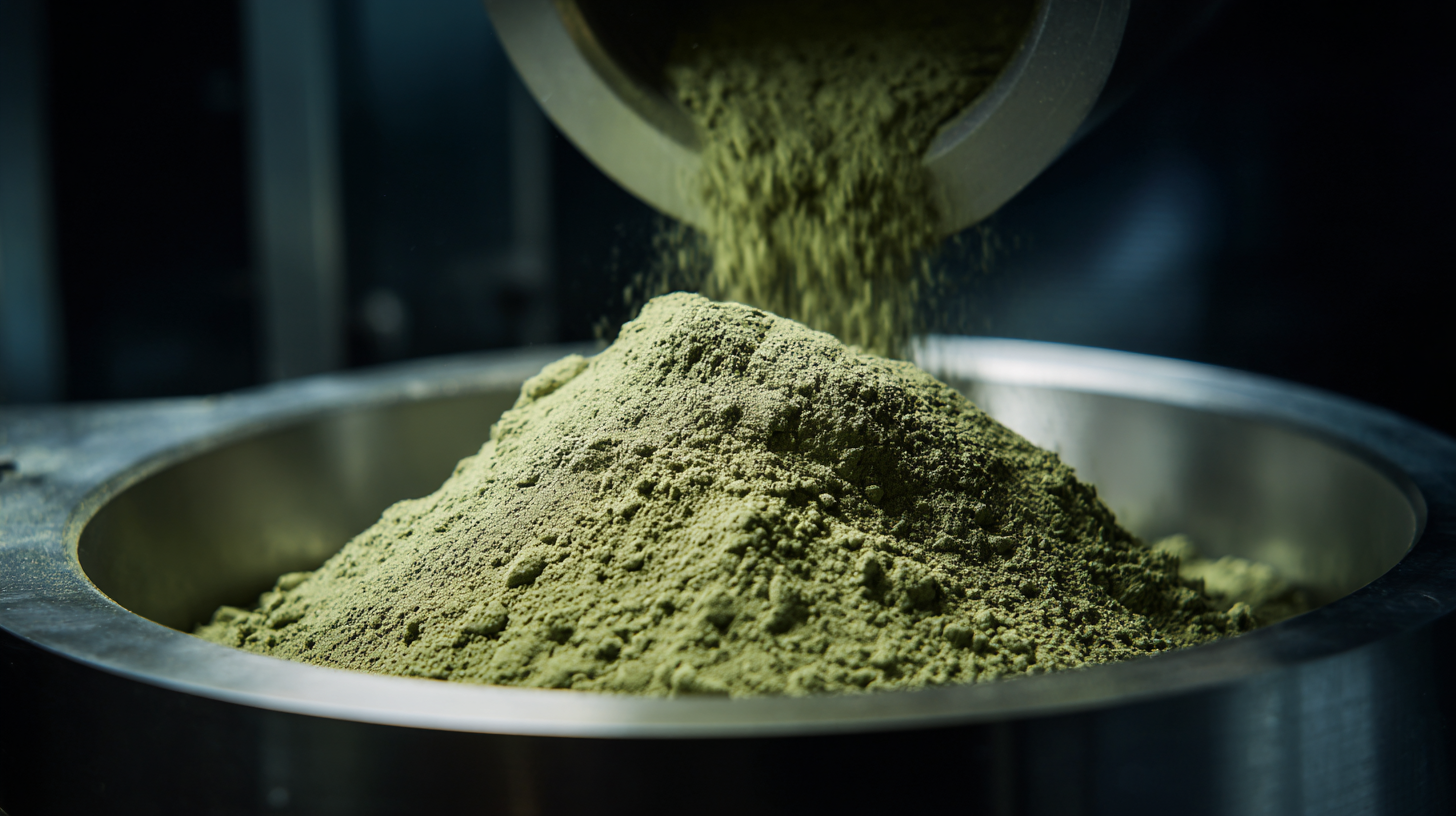

In today's fast-paced manufacturing landscape, the quest for efficiency and innovation is more crucial than ever. One key player in this transformation is the use of Mixer Powder, a versatile ingredient that is reshaping production processes across various industries. From food and pharmaceuticals to cosmetics and chemicals, Mixer Powder applications are proving to be unmatched in their ability to enhance product quality and streamline operations.

This blog delves into five groundbreaking strategies that highlight the significant impact of Mixer Powder on production techniques, demonstrating how companies can leverage these advancements to stay ahead of the competition.

Join us as we explore the transformative power of Mixer Powder and the future it holds for production efficiency.

Innovative Mixer Powder Applications Driving Efficiency in Manufacturing Processes

Innovative mixer powder applications are driving unparalleled efficiency in manufacturing processes across various industries. As highlighted by recent advances in 3D printing technology, the integration of fiber-reinforced composites has revolutionized production in aerospace, automotive, and medical sectors. These materials, known for their outstanding mechanical properties, are increasingly utilized in conjunction with advanced powder mixing techniques, ensuring precise formulation and enhanced performance in complex manufacturing environments.

Moreover, the emergence of multifunctional 3D food printers, capable of quad-screw nozzle printing and dual ink mixing, showcases the versatility of mixer powders in food manufacturing. This technological advancement not only streamlines the production process but also introduces a new level of creativity in food design and customization. Additionally, innovations such as hybrid multi-zonal compartment modeling for continuous powder blending are further refining manufacturing processes by optimizing the mixing parameters and ensuring uniform quality—a critical factor in high-stakes industries like pharmaceuticals and food production.

5 Unmatched Mixer Powder Applications Transforming Your Production Process

This chart illustrates the efficiency improvements driven by innovative mixer powder applications in various manufacturing processes. The data showcases the percentage increase in productivity for five different applications.

Leveraging Customized Formulations for Enhanced Product Quality and Consistency

In today's competitive landscape, leveraging customized formulations in mixer powders is crucial for enhancing product quality and consistency. According to a report by Grand View Research, the global food and beverage industry is projected to reach $8 trillion by 2025, driving the demand for specialized ingredients that cater to specific needs. Customized mixer powders allow producers to create unique flavors, textures, and nutritional profiles, ultimately leading to improved customer satisfaction.

In today's competitive landscape, leveraging customized formulations in mixer powders is crucial for enhancing product quality and consistency. According to a report by Grand View Research, the global food and beverage industry is projected to reach $8 trillion by 2025, driving the demand for specialized ingredients that cater to specific needs. Customized mixer powders allow producers to create unique flavors, textures, and nutritional profiles, ultimately leading to improved customer satisfaction.

Tip: Consider investing in R&D to create formulations that meet the evolving tastes of your target market. By collaborating with ingredient suppliers and utilizing cutting-edge technology, manufacturers can innovate and tailor products that stand out in the crowded marketplace.

Furthermore, a study by Mordor Intelligence highlights that 40% of consumers are willing to pay a premium for products made with high-quality, customized ingredients. This statistic emphasizes the importance of consistency in production processes, which can be achieved through the integration of advanced mixing technologies. These innovations not only enhance the sensory attributes of products but also ensure regulatory compliance, thus establishing a strong brand loyalty among consumers.

Tip: Regularly monitor production consistency with real-time data analytics to address any variances immediately. Implementing such practices can lead to more efficient operations and higher-quality outcomes across your product range.

Boosting Production Speed: How Mixer Powders Optimize Workflow and Reduce Downtime

In today's competitive manufacturing landscape, optimizing production speed is critical for success. One innovative solution that has gained traction is the use of mixer powders, which can significantly enhance workflow efficiency and minimize downtime. According to a report by MarketsandMarkets, the global industrial mixer market is projected to reach $5.4 billion by 2025, driven by the demand for faster and more reliable production processes. Mixer powders facilitate faster mixing and blending, reducing cycle times and allowing for quicker transitions between production batches.

The application of mixer powders can also lead to a notable decrease in equipment wear and tear. A study by the Institute of Manufacturing Excellence highlighted that factories implementing optimized mixing solutions experienced a 20% reduction in machine downtime, resulting in substantial cost savings and increased output. Additionally, these advanced formulations enable manufacturers to maintain consistent product quality while streamlining their operations. The ability to quickly adjust recipes and mix ratios without sacrificing quality is invaluable in meeting fluctuating consumer demands and remaining agile in the ever-evolving market. By leveraging the capabilities of mixer powders, manufacturers can not only boost their production speed but also enhance their overall operational efficiency.

Sustainable Practices: Eco-Friendly Mixer Powder Solutions in Industrial Production

In today's industrial landscape, the push for sustainability has led to innovative solutions that integrate eco-friendly mixer powders into production processes. These tailored formulations not only enhance efficiency but also reduce the environmental footprint of manufacturing. By utilizing biodegradable ingredients and promoting recyclable packaging, companies can achieve their production goals while adhering to sustainable practices. The adoption of such mixer powders is a testament to the commitment of modern industries towards ecological preservation.

Moreover, the implementation of eco-friendly mixer powders doesn't just cater to environmental concerns; it also drives cost-efficiency. By minimizing waste and improving the lifecycle of products, manufacturers can lower their operational costs while enhancing product quality. This dual benefit not only appeals to eco-conscious consumers but also positions brands as leaders in sustainable manufacturing. As businesses increasingly recognize the importance of aligning their production processes with green initiatives, the role of mixer powders in fostering sustainability becomes ever more significant.

Regulatory Compliance: Ensuring Mixer Powder Applications Meet Industry Standards and Safety Protocols

In the ever-evolving landscape of industrial production, compliance with regulatory standards is paramount for mixer powder applications. These applications, pivotal for industries ranging from food and beverage to pharmaceuticals, must adhere to stringent safety protocols to ensure product integrity and consumer safety. According to a report by the Food and Drug Administration (FDA), non-compliance can lead to not only significant financial penalties but also potential harm to public health. Therefore, it is crucial for manufacturers to implement comprehensive quality assurance systems that align with regulations such as the Current Good Manufacturing Practice (cGMP) guidelines.

Moreover, the Occupational Safety and Health Administration (OSHA) emphasizes the importance of workplace safety in the handling of mixer powders. A study by the National Institute for Occupational Safety and Health (NIOSH) indicates that improper management of airborne powder hazards can expose workers to serious health risks, including respiratory issues. Companies utilizing mixer powder technology must invest in technologically advanced mixing solutions that both enhance production efficiency and meet health and safety regulations. Investing in mixer powder applications that prioritize regulatory compliance not only safeguards consumer trust but also fortifies a manufacturer’s position in a competitive market.

Related Posts

-

Top Innovations in Best Powder Mixture Machines: Real-World Applications and Success Stories

-

Exploring Characteristics and Applications of Best Blister Machines in Pharma Manufacturing

-

Ultimate Guide to Choosing the Best Powder Mixers for Your Business Needs

-

Future Innovations in Best Cannabidiol From Hemp Industry by 2025

-

Ultimate Guide to Choosing the Best Capsule Filling Plate for Your Needs

-

How the Best Powder Pulverizer Transforms Food Processing: Industry Case Studies and Insights